Understanding the Mechanics and Applications of Telescopic Bellows in Engineering Systems

Understanding Telescopic Bellows Functionality and Applications

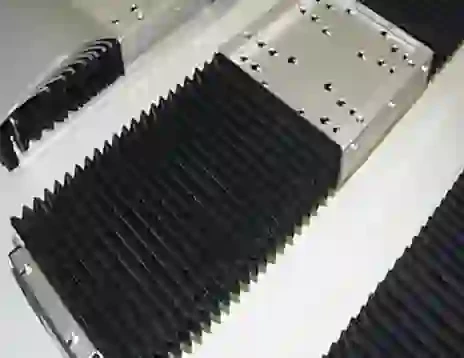

Telescopic bellows are specialized components used in various industries and applications primarily for protection, sealing, and extending the service life of machinery. Their unique design allows them to extend and retract, much like an accordion, providing a highly versatile solution for safeguarding moving parts in machinery and equipment.

Structure and Design

Telescopic bellows are typically made from flexible materials such as rubber, PVC, silicone, or polyurethane. Their design consists of folds or pleats that enable them to expand and contract smoothly. This folding structure not only facilitates movement but also ensures a complete seal when folded, protecting the underlying components from dust, debris, and other environmental factors.

The configuration of telescopic bellows can vary greatly depending on the specific requirements of the application. They can be linear or curved, with varying diameters and lengths to suit different machinery designs. In some instances, custom solutions may be necessary to meet particular operational requirements, leading manufacturers to create tailored products that fit unique specifications.

Functionality

The primary function of telescopic bellows is to provide protection for mechanical parts that undergo linear or angular motion. They are commonly used to cover guideways, shafts, spindles, and other moving parts in machines, such as lathes, milling machines, and CNC equipment. By preventing contaminants from entering critical areas, telescopic bellows play an essential role in enhancing the durability and reliability of machinery.

In addition to protection, telescopic bellows also serve as a damping mechanism that can absorb shocks during operation. This feature is particularly important in machines where precision is vital, as any sudden jolt can degrade performance and accuracy. The flexibility of the bellows allows them to adapt to various movement dynamics without compromising their sealing capabilities.

telescopic bellow

Applications

Telescopic bellows find their applications in numerous sectors, including manufacturing, automotive, aerospace, and semiconductor industries. In the manufacturing sector, they protect machine components and ensure a clean working environment by preventing the ingress of particles that could cause wear or corrosion. In the automotive industry, telescopic bellows are often used to shield steering columns, suspension systems, and drive shafts from debris and moisture, thus extending the life of these components.

In the aerospace sector, where the precision and reliability of mechanical systems are paramount, telescopic bellows provide necessary protection for moving parts exposed to harsh conditions. Similarly, in the semiconductor industry, these bellows play a critical role in maintaining the cleanliness of sensitive equipment, ensuring optimal performance and avoiding contamination.

Advantages

The advantages of using telescopic bellows are multifaceted. First, their ability to protect machinery from contaminants leads to reduced maintenance costs and increased operational efficiency. By minimizing wear and tear, telescopic bellows contribute to the longevity of equipment, reducing the frequency and costs associated with replacements and repairs.

In addition to mechanical protection, telescopic bellows also offer noise reduction, which is beneficial in workplaces where sound levels must be kept to a minimum. Their flexible nature allows them to dampen vibrations and absorb shocks, leading to smoother operation of machinery.

Conclusion

Telescopic bellows are an incredibly effective solution for the protection and functionality of various mechanical systems. With applications spanning multiple industries, they play a crucial role in ensuring the durability and reliability of machinery. As industries continue to evolve, the demand for specialized solutions like telescopic bellows will only grow, underscoring the importance of innovation in this field. By investing in high-quality telescopic bellows, manufacturers can achieve not only operational efficiency but also a significant reduction in maintenance costs, ultimately leading to enhanced productivity and success in their endeavors.