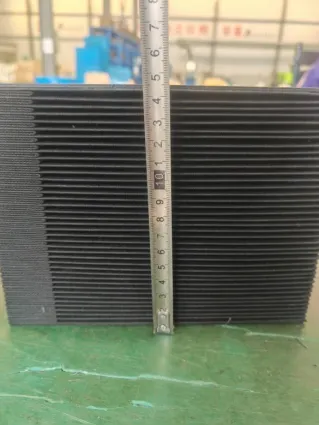

telescopic bellow

The Telescopic Bellow Engineering Marvels of Flexibility and Functionality

In the world of mechanical engineering, the telescopic bellow stands out as an ingenious solution designed to address specific challenges related to movement and protection in various applications. These versatile components serve crucial roles in many industries, from automotive to aerospace, offering flexibility, protection, and efficiency. This article explores the functionality, construction, applications, and importance of telescopic bellows in modern engineering.

What is a Telescopic Bellow?

A telescopic bellow is a flexible, expandable tube-like structure that can extend and contract along its length. This mechanism allows it to adapt to movement or changes in length while protecting the internal components from contaminants, such as dust, dirt, and moisture. Typically made from materials such as rubber, fabric, or plastic, telescopic bellows can be designed to withstand a variety of environmental conditions, including extreme temperatures, chemicals, and mechanical stresses.

Construction and Design

The construction of a telescopic bellow involves careful consideration of material selection and geometry. The most common materials utilized are elastomers, which provide durability and flexibility. Each bellow consists of interconnected folds, allowing it to compress and expand smoothly. The design can vary significantly based on the intended application; for instance, bellows used in high-precision machinery will often feature tighter folds for better accuracy and minimal play, while those used in heavy machinery may prioritize durability over precision.

Advanced manufacturing techniques, such as injection molding and extrusion, are often employed to ensure high-quality production. The design of the bellow must also take into account factors such as loading conditions, travel distances, and operational speed, which all influence the performance and lifespan of the component.

Applications Across Industries

Telescopic bellows find applications across a wide array of industries, demonstrating their versatility and effectiveness

1. Manufacturing Automation In CNC machines and robotics, telescopic bellows are crucial for protecting moving components from contaminants that could hinder precision and lead to failure.

telescopic bellow

2. Automotive Engineering In vehicles, these bellows protect critical components such as steering racks and suspension systems, ensuring they remain clean and operational despite exposure to environmental factors.

3. Aerospace In the aerospace industry, telescopic bellows are used in landing gear and various hydraulic systems to maintain fluid integrity and protect sensitive mechanisms from foreign particles.

4. Medical Devices Telescopic bellows are also utilized in certain medical applications, where they serve to protect mechanical components of devices that undergo frequent movement or exposure to biological materials.

5. Construction Machinery Heavy equipment often operates in challenging environments, making it imperative to use telescopic bellows for safeguarding hydraulic cylinders and other critical areas from dirt and debris.

Importance of Telescopic Bellows

The significance of telescopic bellows transcends their immediate functional benefits. They enhance equipment reliability and longevity, which in turn reduces maintenance costs and downtime—critical factors in highly competitive industries. By preventing the ingress of contaminants, they help ensure that machinery operates at optimal efficiency, ultimately contributing to higher productivity and safety standards.

Moreover, as industries strive for more compact and efficient designs, the role of telescopic bellows becomes even more crucial. Their ability to compress and expand allows for innovative engineering solutions that maximize space without sacrificing functionality. This adaptability is essential in an era where space constraints and efficiency demands are ever-increasing.

Conclusion

In summary, telescopic bellows represent a fusion of engineering ingenuity and practicality. They exemplify the importance of flexibility and protection in mechanical systems across diverse applications. As technology continues to evolve and demands increase, the development and refinement of telescopic bellows will undoubtedly play a significant role in advancing both design and functionality in engineering. Understanding and utilizing these components effectively can lead to more durable, efficient, and reliable systems, highlighting the quintessential role of telescopic bellows in modern engineering.