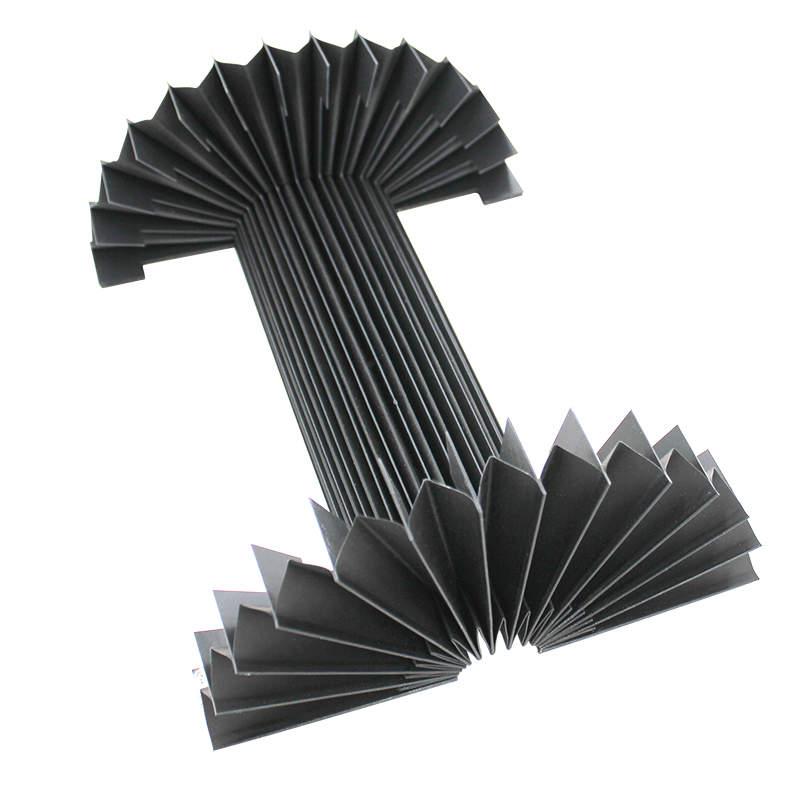

Telescopic Bellow Covers - Durable Protection for Machinery

The Importance of Telescopic Bellow Covers in Mechanical Engineering

Telescopic bellow covers, widely recognized in mechanical engineering, are critical components that enhance the durability and functionality of various machinery. These protective elements, often made from flexible materials, serve to shield sensitive mechanical parts from contaminants such as dust, dirt, moisture, and debris. With advancements in technology and materials science, telescopic bellow covers have evolved to meet the increasing demands of modern machinery, ensuring reliability and longevity in performance.

One of the primary functions of telescopic bellow covers is to protect moving parts. In numerous applications, such as CNC machines, lathes, and industrial robots, precision and cleanliness are paramount. Any foreign particles can lead to wear, tear, and malfunction, resulting in costly downtimes and repairs. By enclosing these components within a bellow cover, manufacturers can significantly reduce the risk of contamination. The flexible design allows the bellows to expand and contract as the machinery operates, maintaining a snug fit without hindering movement.

Moreover, telescopic bellow covers are designed to withstand harsh environmental conditions. They can be crafted from various materials, including rubber, polyurethane, and neoprene, each chosen based on the specific application requirements. For instance, in environments where high temperatures and corrosive substances are present, specialized materials are utilized to ensure that the bellow covers maintain their integrity and performance. This versatility makes them suitable for a wide range of industries, including manufacturing, automotive, and aerospace.

telescopic bellow cover

In addition to protecting equipment, telescopic bellow covers play an essential role in enhancing operator safety. By covering potentially dangerous moving parts, these protective structures help minimize the risk of accidents in industrial settings. Operators are less exposed to machinery's intricate mechanisms, making it safer to work in close proximity to heavy equipment. This feature not only boosts workplace safety but also encourages more efficient operations as employees can concentrate on their tasks without the constant worry of potential hazards.

Another noteworthy aspect of telescopic bellow covers is their contribution to the overall maintenance of machinery. Regular maintenance is crucial for optimal performance, and a clean machine is easier to service. By keeping contaminants at bay, these covers extend the lifespan of machinery, reduce maintenance frequency, and lower the overall operational costs. This, in turn, provides businesses with a competitive edge, as less downtime and lower maintenance expenses directly impact productivity and profitability.

In conclusion, telescopic bellow covers are an indispensable component of modern mechanical systems. Their ability to protect delicate machinery from harmful contaminants, enhance operator safety, and reduce maintenance needs underscores their critical role in various industries. As technology continues to advance, the development of innovative materials and designs for these covers will likely enhance their functionality and adaptability, further solidifying their place in the realm of mechanical engineering. Companies investing in high-quality telescopic bellow covers can expect improved machinery performance, reduced downtime, and ultimately, greater operational efficiency.