synchronous v belt

Understanding Synchronous V Belts Applications and Benefits

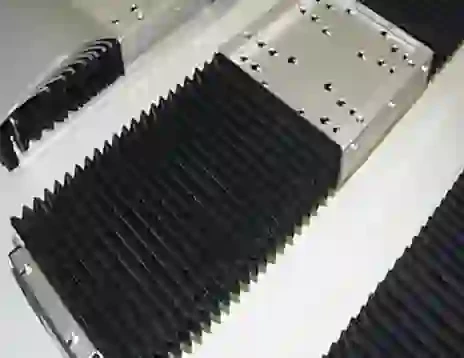

Synchronous V belts, often referred to simply as timing belts, are a vital component in various mechanical systems that require precise motion control. Unlike traditional belts, synchronous V belts are engineered to stay in constant tension and synchronize the rotational speed of various components, making them ideal for applications where timing is crucial.

Structure and Design

Synchronous V belts are constructed from high-quality materials, typically reinforced with fibers such as polyester or aramid to enhance strength and durability. The belt features teeth on its inner surface that mesh precisely with matching grooves on pulleys. This unique design ensures that there is minimal slippage, allowing for efficient transmission of torque and power. The most common profile of these belts includes trapezoidal teeth, which enable better engagement with the pulleys.

The choice of material also plays a significant role in the performance of synchronous V belts. Most belts are made from neoprene or other synthetic rubber compounds that offer resistance to wear and temperature fluctuations. Advanced options may also incorporate high-performance materials to further improve performance in demanding environments.

Applications

Synchronous V belts are widely used across various industries due to their reliability and efficiency. Here are some key applications

1. Automotive Industry These belts are commonly found in vehicles, connecting the crankshaft to other essential components like the camshaft and water pumps. Their ability to maintain precise timing is critical in ensuring optimal engine performance and efficiency.

2. Manufacturing Equipment In factories, synchronous V belts are used in conveyor systems, robotics, and CNC machines. These belts facilitate smooth motion transfer, which is vital for maintaining accuracy in production lines.

3. Agricultural Machinery Tractors and harvesters often utilize synchronous V belts to connect different mechanical parts. The need for precise timing in these machines makes belts critical for operations ranging from planting to harvesting.

4. Home Appliances Many common appliances, such as washing machines and food processors, rely on synchronous V belts for their mechanical operations. These belts contribute to the efficiency and longevity of the devices.

synchronous v belt

5. HVAC Systems In heating, ventilation, and air conditioning systems, synchronous V belts are employed to drive blowers and compressors. Their reliable performance helps maintain a consistent airflow, which is essential for system efficiency.

Advantages of Synchronous V Belts

The use of synchronous V belts comes with numerous benefits that make them the preferred choice in various applications

- High Efficiency With reduced slippage and the ability to transfer power efficiently, synchronous V belts can enhance the overall performance of the machinery they drive.

- Reduced Maintenance These belts typically require less maintenance compared to traditional belts. Regular inspections are often sufficient, as their robust design minimizes wear and elongation.

- Precise Timing Synchronous V belts provide exact timing in power transmission, making them indispensable in applications where coordinated movement is essential.

- Noise Reduction These belts operate more quietly than standard belts, contributing to a more pleasant work environment in industrial settings.

- Versatility Available in various sizes, lengths, and tooth profiles, synchronous V belts can be tailored to meet the specific needs of different applications, enhancing their usability across a broad spectrum of industries.

Conclusion

In conclusion, synchronous V belts are an integral component in many mechanical systems, providing reliable and efficient power transmission. Their unique design and benefits make them essential in various applications, from automotive to industrial uses. As technology continues to evolve, the demand for these belts is likely to increase, further solidifying their place in the machinery and equipment of the future. Whether in a factory, a vehicle, or at home, the impact of synchronous V belts on performance and efficiency is undeniable.