synchronous timing belt

Understanding Synchronous Timing Belts

Synchronous timing belts are critical components in various mechanical systems, particularly in automotive and industrial applications. These belts are designed to synchronize the rotation of shafts, ensuring precise timing between moving parts. The unique design of synchronous belts allows them to maintain accurate timing and efficiency, making them indispensable in machines where timing is crucial.

What is a Synchronous Timing Belt?

A synchronous timing belt, also known as a toothed belt, is a looped belt with teeth that fit into corresponding grooves on pulleys or gears. This design allows for a direct, non-slip transfer of motion and power from one component to another. The lack of slipping is what distinguishes synchronous timing belts from standard V-belts, which can experience slippage under load.

The teeth on a synchronous belt enable it to mesh perfectly with the pulleys, ensuring that the belt remains engaged even under varying loads. This characteristic is particularly important in applications such as engine timing systems, where precise synchronization between the crankshaft and camshaft is necessary for optimal engine performance.

Advantages of Synchronous Timing Belts

1. Precision and Accuracy One of the primary advantages of synchronous timing belts is their ability to provide precise timing. This accuracy is essential in machines where even slight deviations can lead to inefficiencies or failures.

2. Reduced Maintenance Synchronous belts typically require less maintenance compared to chains and mechanical systems. They do not need lubrication and have fewer moving parts that could wear out over time, contributing to lower maintenance costs.

3. High Efficiency The design of synchronous belts allows for efficient power transmission. They can transmit more power over longer distances compared to other types of belts, making them suitable for various industrial applications.

4. Noise Reduction Synchronous belts operate more quietly than traditional chain or gear systems. This characteristic makes them ideal for applications in environments where noise reduction is a priority.

5. Versatility These belts are used in a wide range of applications, from automotive engines to conveyor systems in manufacturing plants. Their ability to handle different power requirements and environments adds to their versatility.

Applications of Synchronous Timing Belts

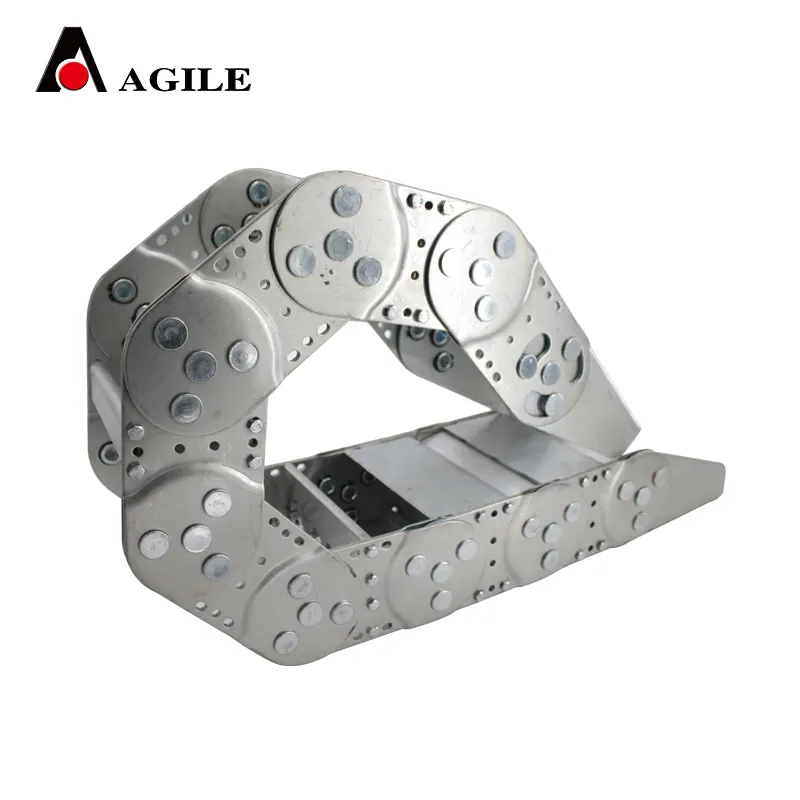

synchronous timing belt

Synchronous timing belts are utilized in a plethora of applications across various industries. In the automotive sector, these belts play a crucial role in engine timing systems. They ensure that the engine's camshaft and crankshaft rotate in perfect synchronization, which is vital for the proper functioning of the engine.

In the industrial realm, synchronous belts are commonly found in conveyor systems, robotic arms, and CNC machines. These systems require precise timing to operate efficiently, making synchronous belts an ideal choice. Additionally, they are used in printing machines, textile machinery, and packaging equipment, demonstrating their versatility across different manufacturing environments.

Choosing the Right Synchronous Timing Belt

When selecting a synchronous timing belt for a specific application, several factors must be considered

1. Belt Width The width of the belt influences its load-carrying capacity. A wider belt can handle more power but may also take up more space.

2. Length Accurate measurement of the required belt length is crucial to ensure proper fit and function.

3. Pitch The pitch refers to the distance between the centers of the teeth. Selecting the correct pitch is essential for compatibility with the pulleys.

4. Material Synchronous belts are made from various materials, including rubber and polyurethane. The choice of material can affect the belt's durability, temperature resistance, and overall performance.

5. Operating Conditions The specific environmental conditions, such as temperature, humidity, and exposure to chemicals, should influence the choice of synchronous timing belt. Some belts are designed for high-temperature applications, while others are better suited for wet or corrosive environments.

Conclusion

Synchronous timing belts are essential components in modern machinery, providing precision, efficiency, and reliability in power transmission. Their design helps to minimize slippage, reduce noise, and decrease maintenance needs, making them ideal for a wide range of applications. Understanding their features and applications can help industries select the right timing belt, ultimately leading to improved operational efficiency and performance. As technology continues to evolve, the role of synchronous timing belts will remain significant in driving the advancement of mechanical systems.