Understanding the Functionality and Benefits of Synchronous Timing Belts in Mechanical Systems

Understanding Synchronous Timing Belts An Essential Component in Mechanical Systems

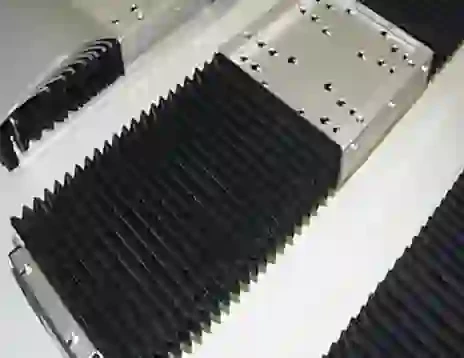

Synchronous timing belts play a crucial role in various mechanical systems within the engineering and manufacturing sectors. These belts, characterized by their toothed design, are essential for transferring motion and power between rotating shafts with precision and reliability. Unlike traditional V-belts, synchronous belts are engineered to eliminate slippage, ensuring that the timing between connected components remains consistent. This article explores the importance, applications, and advantages of synchronous timing belts in modern machinery.

What is a Synchronous Timing Belt?

A synchronous timing belt, often referred to as a timing belt, is a flexible loop made of rubber or polyurethane, reinforced with fibers such as polyester or Kevlar for added strength. The defining feature of synchronous belts is their toothed structure, which interlocks with corresponding gears or pulleys. This design allows it to maintain a constant distance between the centers of the pulleys, ensuring synchronous motion, hence the name.

Applications of Synchronous Timing Belts

Synchronous timing belts are widely used across various industries, including automotive, aerospace, manufacturing, and robotics. In automotive applications, timing belts synchronize the rotation of the crankshaft and camshaft, ensuring that engine valves open and close at the correct intervals. This synchronization is vital for optimal engine performance and efficiency.

In manufacturing, synchronous belts are fundamental in conveyor systems, where they transport materials and products with precision. Their ability to maintain consistent speed and timing reduces the risk of jams or product misalignment, resulting in an efficient production line.

Robotics and automation systems also heavily rely on synchronous timing belts. They allow for precise control of robotic arms and automated machinery, where accuracy in movement is paramount. The belts contribute to the reliability and repeatability of these systems, which is crucial for production quality.

synchronous timing belt

Advantages of Synchronous Timing Belts

The advantages of utilizing synchronous timing belts in various applications are numerous. Firstly, their ability to deliver precise timing and alignment drastically reduces the likelihood of mechanical failure due to slippage. This consistency contributes to the overall longevity of machinery and minimizes maintenance costs.

Secondly, synchronous belts operate quietly compared to other types of power transmission systems, such as chains or gear drives. This quiet operation is particularly beneficial in environments where noise reduction is a priority, such as in office equipment or household appliances.

Moreover, synchronous timing belts are less susceptible to wear and tear when properly maintained. They have a longer operational life than many alternative systems, which means reduced downtime for replacements and repairs. Their lightweight design also contributes to energy efficiency, as less power is required to drive them compared to heavier alternatives.

Additionally, synchronous timing belts require minimal tensioning, which simplifies installation and maintenance. With fewer parts to manage compared to chain drives or other mechanical systems, they also provide a more streamlined solution for designers and engineers.

Conclusion

Synchronous timing belts are an integral part of modern engineering and manufacturing processes. Their unique design and functional advantages make them indispensable in applications requiring precision timing and reliability. As technology continues to advance, the importance of efficient power transmission systems will only grow, cementing the role of synchronous timing belts in the future of mechanical design.

Overall, understanding the fundamental principles and applications of synchronous timing belts allows engineers and technicians to make informed decisions that enhance the efficiency and reliability of various mechanical systems. Their versatility and performance have proven essential in ensuring that machinery operates seamlessly, contributing to the overall progress of industrial technology.