Understanding the Benefits and Uses of Synchronous Round Belts in Various Applications

The Importance of Synchronous Round Belts in Modern Machinery

In the world of mechanical engineering and manufacturing, the functionality and efficiency of machinery can often hinge on the smallest components. One such critical component is the synchronous round belt, a type of belt that plays a crucial role in various applications, from automotive engines to industrial machinery. This article delves into the characteristics, advantages, and applications of synchronous round belts, highlighting their importance in modern engineering.

Understanding Synchronous Round Belts

Synchronous round belts are designed to transmit power between rotating shafts with minimal slippage. Unlike traditional V-belts or flat belts, synchronous belts rely on a system of teeth or profiles that engage with corresponding grooves on pulleys. This design allows for precise and efficient power transfer, reducing the risk of belt slippage and increasing the overall reliability of the system. The round shape of the belt aids in flexibility, enabling it to navigate around different pulley sizes and configurations.

Advantages of Synchronous Round Belts

One of the standout characteristics of synchronous round belts is their ability to maintain a high degree of synchronization between connected components. This quality is essential in applications where timing is critical, such as in robotics or conveyor systems. By ensuring that the connected shafts rotate at precisely the same speed and position, synchronous round belts contribute to smoother operation and enhanced performance.

Another significant advantage of these belts is their durability. Synchronous round belts are often made from high-quality materials resistant to wear, temperature fluctuations, and environmental factors. This durability translates to a longer lifespan and, subsequently, reduced maintenance costs for machine operators. Consequently, the lower maintenance needs associated with synchronous round belts make them an economically advantageous choice for businesses in demanding industrial sectors.

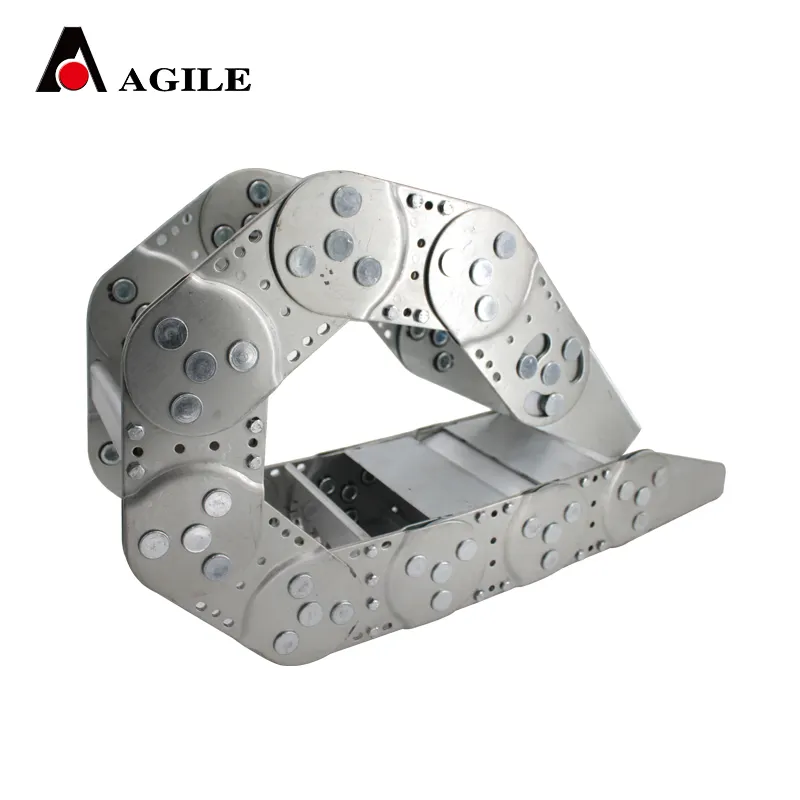

synchronous round belt

Moreover, synchronous round belts operate quietly compared to traditional belt systems. The elimination of slippage and the secure engagement of teeth lead to minimal noise during operation. This feature is particularly beneficial in environments where noise reduction is a priority, such as in automated manufacturing processes or office equipment.

Applications of Synchronous Round Belts

Synchronous round belts find applications across various industries due to their unique properties. One of the most prominent uses is in the automotive sector, where they are employed in timing systems to ensure that the engine’s valves open and close at the correct timing in relation to the pistons. This precision is critical for optimal engine performance and efficiency.

In the manufacturing realm, synchronous round belts are frequently used in conveyor systems, where they assist in the smooth and efficient transport of goods. Their ability to maintain an exact speed allows for precise control over production processes, contributing to improved workflow and productivity.

Furthermore, they are widely used in robotics, where precise movements and synchronization are paramount. Synchronous round belts facilitate the intricate movements required in robotic arms and automated systems, ensuring that each part operates in harmony with the others.

Conclusion

The emergence of synchronous round belts has revolutionized the way power is transmitted in machinery. Their ability to maintain synchronization, coupled with exceptional durability and low maintenance requirements, makes them an indispensable asset in various industries. As technology continues to advance, the relevance of synchronous round belts will likely only increase, driving efficiency and performance in an ever-evolving mechanical landscape. Understanding and leveraging the benefits of these belts is crucial for engineers and manufacturers aiming to optimize their processes and deliver high-quality products. In this light, synchronous round belts are not just a component of machinery; they are a cornerstone of modern engineering excellence.