Synchronous Round Belt Innovations for Efficient Power Transmission and Motion Control Solutions

Exploring Synchronous Round Belts An Essential Component in Modern Mechanical Systems

In the ever-evolving landscape of mechanical engineering, the design and implementation of efficient power transmission systems play a pivotal role. Among the various components considered in these systems, the synchronous round belt has garnered significant attention. Its unique properties and advantages make it an essential choice for various applications, from manufacturing to robotics.

Understanding Synchronous Round Belts

Synchronous round belts, often known for their circular cross-section, are a type of power transmission belt that operates on the principle of synchronous motion. Unlike traditional V-belts or flat belts that may slip or lose contact under tension, synchronous round belts maintain a consistent grip on pulleys, ensuring precise timing and motion. This characteristic is particularly beneficial in applications where synchronization is crucial, such as conveyor systems and robotic mechanisms.

The round design of these belts allows for flexibility and ease of installation, making them an attractive option for engineers and designers. They can easily accommodate different routing configurations and complex setups, which is a significant advantage in constrained spaces or intricate layouts.

Advantages of Synchronous Round Belts

1. High Efficiency Synchronous round belts are designed to minimize energy loss during transmission. Their precision-engineered teeth engage with similarly designed pulleys, reducing slippage and ensuring efficient transfer of power.

2. Durability Made from high-quality materials such as polyurethane or rubber combined with fiberglass reinforcement, these belts exhibit remarkable resistance to wear and environmental factors. This durability translates to longer service life and lower maintenance costs.

3. Versatility One of the standout features of synchronous round belts is their adaptability to a wide range of applications. They are utilized in various industries, including automotive, textile, packaging, and automation, making them a versatile choice for engineers.

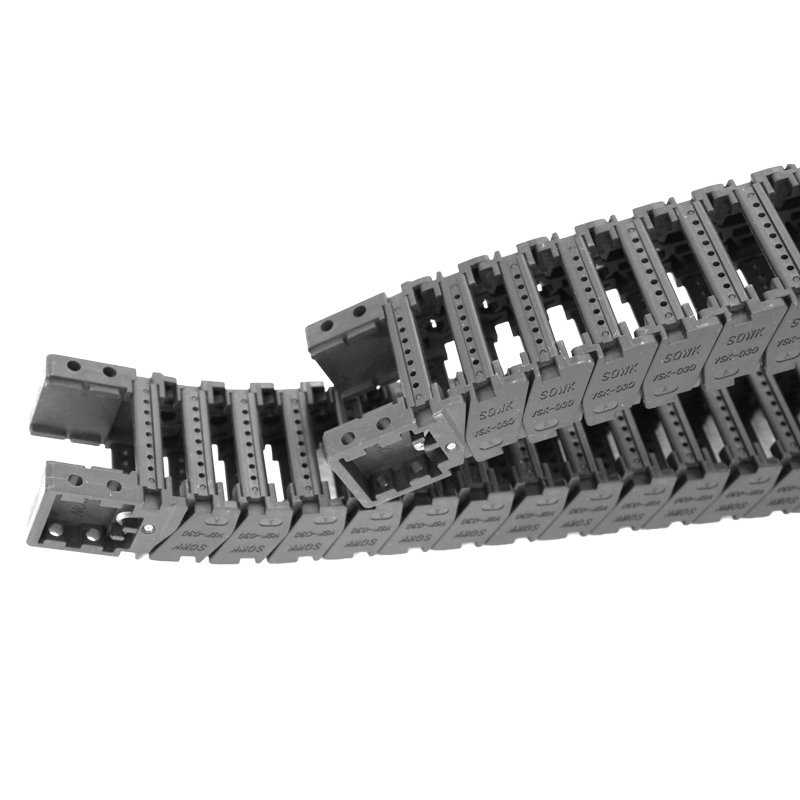

synchronous round belt

4. Noise Reduction The design of these belts often results in quieter operation compared to traditional belt systems. This noise reduction is an important consideration in environments where sound levels need to be controlled, improving overall workplace conditions.

5. Lightweight Design Synchronous round belts are generally lighter than their flat or V-belt counterparts. This characteristic helps reduce the overall weight of machinery, contributing to efficiency and performance, particularly in mobile applications.

Applications in Various Industries

In the automotive industry, synchronous round belts are commonly used in timing applications where precise movement between engine components is essential. Their reliability ensures that the engine runs smoothly, preventing potential mechanical failures.

In the packaging sector, these belts are employed in conveyor systems for transport and sorting. Their ability to synchronize movement and maintain a steady grip on items ensures accurate positioning, which is crucial for effective packing and shipping processes.

Robotics has also seen significant advancements through the use of synchronous round belts. In robotic arms and automated machinery, these belts help maintain precise movements, enhancing the overall functionality and performance of robotic systems.

Conclusion

The synchronous round belt is a remarkable innovation in the realm of power transmission. Its unique design coupled with several advantages makes it an invaluable component in various mechanical systems. As industries continue to evolve and demand more efficient and reliable solutions, the role of synchronous round belts will undoubtedly become more pronounced.

Understanding their benefits and applications not only aids engineers in selecting the right components but also propels industries towards achieving improved performance, durability, and efficiency in their operations. As we look toward the future, the synchronous round belt will continue to be integral in the development of advanced mechanical systems, marking the importance of innovation in engineering and technology.