Understanding the Principles of Synchronous Pulleys in Mechanical Systems

Understanding Synchronous Pulleys Mechanisms and Applications

Synchronous pulleys are essential components in mechanical engineering, widely utilized in various machinery and systems to ensure synchronized movement and efficient power transmission. Understanding their design, functionality, and applications is crucial for engineers and technicians working in fields such as manufacturing, automotive, and robotics.

What are Synchronous Pulleys?

Synchronous pulleys, also referred to as timing pulleys, are devices that transmit power and motion using a belt or chain with teeth that mesh perfectly with grooves on the pulleys. This design ensures that the movement between the pulley and the belt is synchronized, meaning that the rotation of the pulley directly corresponds to the movement of the belt, maintaining a fixed relationship between the two. This synchronization is critical in systems where precise timing and positioning are required.

The key feature of synchronous pulleys is their tooth engagement, which prevents slippage and allows for the transfer of torque with high efficiency. Unlike traditional pulleys that rely solely on friction, synchronous pulleys are designed to provide a positive engagement, making them suitable for applications that require accuracy and reliability.

Design Considerations

When designing synchronous pulley systems, several factors must be considered

1. Tooth Profile The shape and size of the teeth on both the pulley and the belt must be compatible to ensure proper engagement. Common tooth profiles include trapezoidal, round, and square shapes, each offering unique advantages in specific applications.

2. Belt Material The material used for the synchronous belt can significantly affect performance. Common materials include rubber and polyurethane, often reinforced with fibers for increased strength and durability.

3. Pulley Material Similarly, the construction material of the pulley influences its weight, strength, and resistance to wear. Pulleys can be made from metals like aluminum or steel, or from engineering plastics, depending on the application requirements.

4. Size and Configuration The size of the pulleys and arrangement of the system are vital for optimizing torque transfer and minimizing frictional losses. Proper alignment is also necessary to ensure the longevity of the system.

Applications of Synchronous Pulleys

Synchronous pulleys have a broad range of applications across various industries. Here are some notable examples

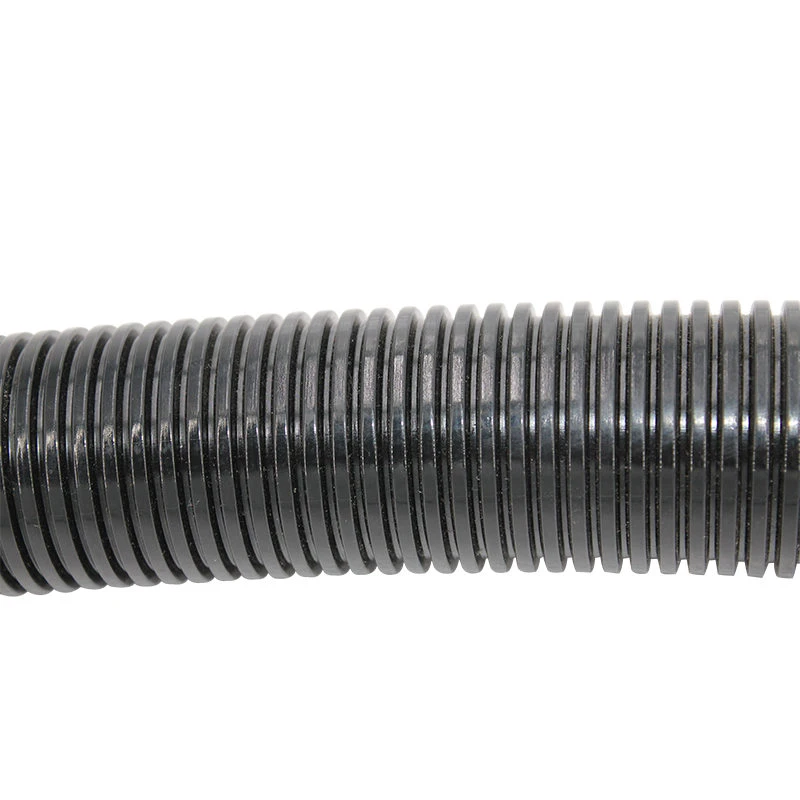

synchronous pulley

- Automotive Industry In vehicles, synchronous pulleys are employed in timing belts that synchronize the rotation of the crankshaft and camshaft, ensuring that engine valves open and close at the correct times. This synchronization is crucial for engine performance and efficiency.

- Robotics Many robotic systems use synchronous pulleys in their drive systems to achieve precise motion control

. This is particularly important in robotic arms or mechanisms where high accuracy is required for repetitive tasks.- Manufacturing Equipment In assembly lines and manufacturing machines, synchronous pulleys help maintain the timing of conveyors and other moving parts. This synchronization ensures that products move through various stages of production without delays or misalignment.

- Textile Industry Synchronous pulleys are used in textile machinery to control the movement of fabric and ensure consistent tension and speed during production processes.

Advantages of Synchronous Pulleys

The use of synchronous pulleys offers several advantages over traditional belt systems

- Precision The positive engagement between the pulley and belt ensures that there is no slipping, resulting in accurate timing and positioning.

- Efficiency Synchronous systems typically have lower power losses compared to friction-based systems, making them more energy-efficient.

- Durability High-quality materials and design reduce wear and tear, extending the lifespan of the belt and pulleys.

- Low Maintenance Synchronous systems require less maintenance than traditional systems, primarily due to reduced friction and slippage.

Conclusion

In summary, synchronous pulleys are vital components in modern mechanical systems that require precise movement and synchronization. Their design, functionality, and wide range of applications highlight their importance in various industries, making them indispensable tools in engineering and technology. As engineering advances continue to evolve, the role of synchronous pulleys will likely expand, further enhancing their applications in innovative technologies. Understanding these mechanisms can significantly contribute to more efficient designs and improved system performance across numerous fields.