Understanding the Mechanics of Synchronous Belt Wheels in Power Transmission Systems

Understanding Synchronous Belt Wheels Engineering Marvels in Motion

Synchronous belt wheels are essential components in the world of mechanical engineering, playing a pivotal role in the transmission of power and motion in various machines and automotive applications. These wheels, designed to work in conjunction with synchronous belts, ensure that mechanical systems operate smoothly and efficiently. In this article, we will delve into the intricacies of synchronous belt wheels, their design, operation, advantages, and applications.

Design and Functionality

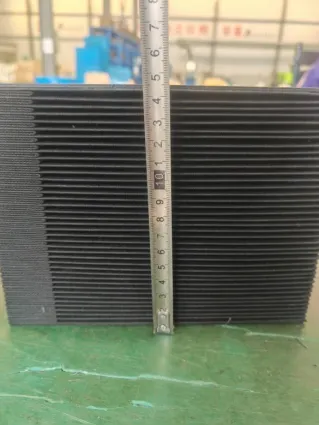

Synchronous belt wheels, often referred to as pulleys, are characterized by their teeth that mesh with the teeth of synchronous belts. This toothed design is what differentiates synchronous belts from traditional v-belts. Instead of sliding, as in a v-belt system, the teeth of a synchronous belt engage with the cogs of the pulley, creating a positive engagement that prevents slippage. This ensures that the input and output shafts remain in precise synchronization.

The materials used in the construction of synchronous belt wheels typically include aluminum, steel, or plastic. The choice of material depends on factors such as the load requirements, environmental conditions, and the specific application. The wheels can vary in size and tooth profile, tailored to meet the requirements of different systems.

Advantages of Synchronous Belt Wheels

The incorporation of synchronous belt wheels offers several advantages compared to other types of power transmission systems. Here are some key benefits

1. High Efficiency Synchronous belt systems are highly efficient, with efficiency rates often exceeding 95%. This means less energy is wasted through friction, leading to reduced operational costs.

2. Precision Timing Because the teeth of the belt and wheel are in constant engagement, synchronous belt systems provide precise timing, making them ideal for applications where synchronization is critical.

3. Minimal Maintenance Synchronous belts typically require minimal maintenance compared to other belt types. They do not need regular tension adjustments, and they are less prone to wear and tear.

synchronous belt wheel

5. Versatility Synchronous belt wheels can be used in a wide variety of applications, from automotive engines to industrial machinery, making them a versatile choice for many engineers.

Applications

Synchronous belt wheels find applications across numerous industries. Some key areas include

- Automotive In vehicle engines, synchronous belts are often used to drive camshafts and ensure that the engine's moving parts operate in sync. This is critical for optimal engine performance and efficiency.

- Industrial Machinery Many machines in manufacturing and production environments use synchronous belt systems for conveyor systems, robotic arms, and assembly lines, allowing for precise movements and timing.

- HVAC Systems Synchronous belts are employed in heating, ventilation, and air conditioning systems to drive fans and blowers, contributing to effective air management.

- Office Equipment Printers and copiers often use synchronous belts for precise paper movement and timing during the printing process.

Conclusion

Synchronous belt wheels represent a fusion of engineering precision and functionality, providing reliable power transmission solutions across diverse industries. Their unique design facilitates high efficiency, precision timing, and low maintenance, making them indispensable in modern machinery and automotive systems.

As technology continues to advance, the role of synchronous belt wheels will likely expand, further enhancing their applications in various fields. Understanding these components not only aids engineers in designing efficient systems but also highlights the importance of meticulous engineering in our daily lives. Through the continued innovation surrounding synchronous belts and wheels, we can expect to see even more remarkable developments in motion control and power transmission technologies in the future.