synchronous belts and pulleys

Understanding Synchronous Belts and Pulleys

Synchronous belts and pulleys are fundamental components in various mechanical systems, playing crucial roles in power transmission. Their design and functionality make them integral to applications ranging from automotive engines to industrial machinery. This article explores the principles behind synchronous belts and pulleys, their advantages, and their applications, providing a comprehensive overview of these essential mechanical elements.

The Basics of Synchronous Belts

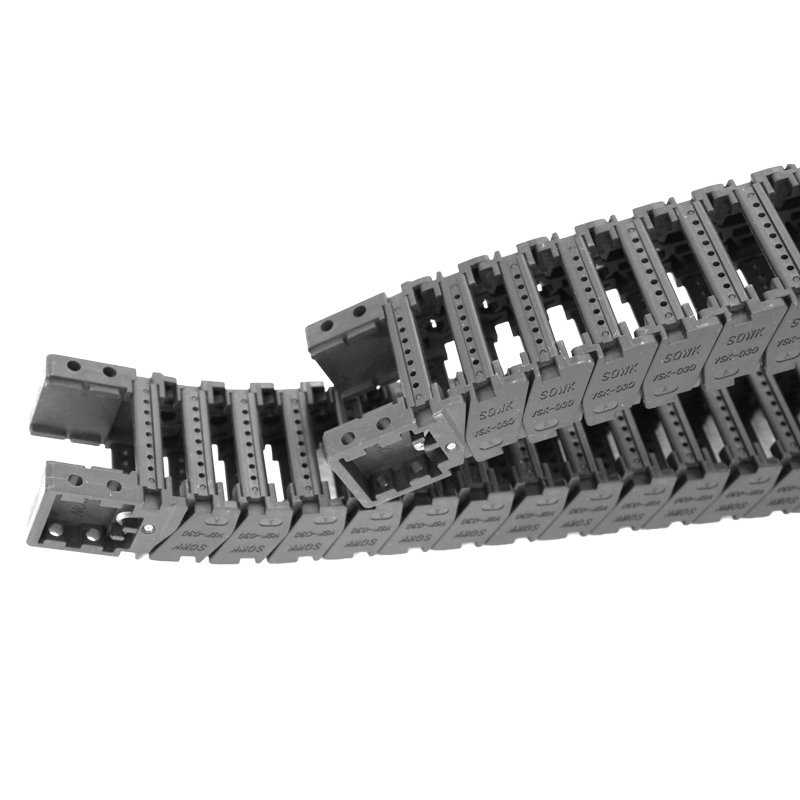

Synchronous belts, often referred to as timing belts, are uniquely designed to provide precise and reliable synchronization between rotating components. Unlike traditional belts, which can slip and lose synchronization, synchronous belts engage with notched pulleys, ensuring that the movement of one component directly drives another without any slippage. This characteristic is vital in applications where timing is critical, such as in camshaft and crankshaft operations in internal combustion engines.

Synchronous belts are typically made from durable materials such as neoprene, reinforced with fiberglass or steel for added strength. The notches on the belt align with corresponding grooves on the pulleys, allowing for optimal grip and minimizing wear over time. The design not only enhances performance but also extends the lifespan of both the belt and the pulleys.

The Role of Pulleys

Pulleys are essential components that work in conjunction with synchronous belts. They can be designed in various sizes and configurations, depending on the application. The key function of a pulley is to change the direction of force or to alter the speed and torque of the connected shaft. In synchronous systems, the pulleys typically have teeth that match the notches on the belt, ensuring a tight fit and efficient power transfer.

The diameter of pulleys can be adjusted to modify the speed ratio between the driving and driven components. For instance, using a smaller pulley on the driving side and a larger pulley on the driven side will increase the speed of the driven component while reducing its torque. Conversely, using larger drivers will yield higher torque and reduced speed. This versatility makes synchronous belts and pulleys valuable in various settings, allowing for precise control over mechanical performance.

Advantages of Synchronous Belts and Pulleys

1. Precision and Reliability One of the most significant advantages of synchronous belts is their ability to maintain precise timing between the driving and driven components. This precision is critical in applications where exact timing is necessary for the system to function correctly.

synchronous belts and pulleys

2. High Efficiency Synchronous belts and pulleys are highly efficient. Given that there is no slipping, the energy lost during power transmission is minimal compared to other belt types. This efficiency contributes to overall system performance and can lead to lower operational costs.

3. Reduced Maintenance Synchronous systems typically require less maintenance than their counterparts, such as chains or rubber belts. The absence of lubrication needs and the reduced wear due to the matching teeth results in longer intervals between maintenance checks.

4. Noise Reduction With minimal vibration and slip, synchronous belts operate quietly, reducing operational noise. This is particularly important in applications where noise levels must be controlled for comfort or regulatory reasons.

5. Customization Synchronous belts and pulleys are available in a variety of materials, sizes, and configurations, allowing for customization to meet specific application demands. This adaptability makes them suitable for a wide range of industries, from automotive to manufacturing.

Applications of Synchronous Belts and Pulleys

Synchronous belts and pulleys are ubiquitous across many sectors due to their versatility. In the automotive industry, they are crucial for synchronizing engine operations, including valve timing and variable camshaft timing systems. In industrial applications, they are used in conveyor systems, CNC machinery, and robotics, where precise control of movement is vital.

Additionally, they find uses in household appliances, such as washing machines and food processors, where reliable and efficient power transmission is necessary. The capacity to reduce noise levels while providing precise control makes them an ideal choice for both consumer and industrial products.

Conclusion

Synchronous belts and pulleys offer an extraordinary solution for precise power transmission in various mechanical systems. Their ability to synchronize movement without slippage, coupled with their efficiency and low maintenance requirements, makes them indispensable in countless applications. As technology continues to advance, the development of even more specialized synchronous systems is likely, further enhancing their importance in modern machinery and engineering. Understanding their functions and benefits is key for professionals in engineering and manufacturing fields, shaping the way we design and implement mechanical systems.