Exploring the Mechanics and Applications of Synchronous Belt Drives in Modern Engineering

The Synchronous Belt Drive An Overview

The synchronous belt drive, a critical component in modern mechanical systems, is renowned for its precision, efficiency, and reliability. Unlike traditional belt drives that rely on friction to transfer power, synchronous belt drives utilize teeth embedded in the belt and cogged pulleys to ensure a synchronous motion between the connected shafts. This unique design leads to enhanced timing accuracy and minimizes slippage, making it an ideal choice in various applications.

One of the primary advantages of a synchronous belt drive is its ability to maintain accurate timing over long periods and under high loads

. This characteristic is particularly beneficial in machinery where precise motion control is crucial, such as in robotics, automotive engines, and conveyor systems. The positive engagement of the belt teeth with the pulley grooves ensures that the system operates smoothly and predictably, thus preventing the mechanical components from experiencing unnecessary wear and tear.Synchronous belt drives are typically constructed from a combination of materials designed to withstand significant stress while providing flexibility. The belts are often made from high-strength synthetic materials such as neoprene or polyurethane, reinforced with fiberglass or steel cords for added durability. These materials enable the belts to handle varying loads and operate over a wide temperature range, making them suitable for both industrial and automotive applications.

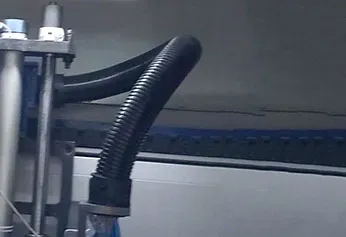

synchronous belt drive

Maintenance is another area where synchronous belt drives shine. Unlike chain drives that may require regular lubrication and adjustment, synchronous belts generally need minimal upkeep. Regular inspection for wear and proper alignment can ensure longevity and optimal performance. When replacement is necessary, the process is straightforward, reducing downtime in industrial settings.

In recent years, the use of synchronous belt drives has expanded beyond traditional applications. They are now found in advanced technologies including 3D printing, automated assembly systems, and even home appliances. Their ability to transmit power efficiently makes them preferable in designs where energy conservation is a priority.

In conclusion, the synchronous belt drive represents a significant advancement in mechanical power transmission systems. With their precision, efficiency, and low maintenance requirements, they have carved a niche for themselves in a wide array of applications. As technology continues to evolve, the synchronous belt drive will undoubtedly play a pivotal role in shaping the future of machinery and automation.