Understanding the Basics of Synchronous Belt Drive Systems and Their Applications

Understanding Synchronous Belt Drives Mechanism, Applications, and Advantages

Synchronous belt drives are an integral part of modern mechanical engineering, widely utilized in various industries for their efficiency and reliability. These systems use toothed belts and pulleys, which operate in sync with each other to ensure precise motion transfer. Unlike traditional belt drives, which can slip and lead to inaccuracies, synchronous drives maintain a fixed relationship between the driving and driven components, making them ideal for applications requiring precise timing.

Mechanism of Synchronous Belt Drives

At the heart of a synchronous belt drive system are three main components the synchronous belt, the pulleys (or sprockets), and the driving motor. The synchronous belt, made from a composite material with teeth molded into its inner side, is designed to mesh perfectly with the teeth of the pulleys. This design allows for a firm grip, ensuring that the belt does not slip off during operation.

The system operates on the basis of positive engagement, where the teeth of the belt fit securely into the grooves of the pulleys. When the motor turns the driving pulley, it pulls the synchronous belt, which in turn rotates the driven pulley at a consistent speed ratio. The result is a smooth, synchronized motion that is critical in applications like robotics, conveyor systems, and printing machines, where precision is paramount.

Applications of Synchronous Belt Drives

Synchronous belt drives are employed across a vast array of applications. In the automotive industry, they play a crucial role in timing mechanisms, such as in timing belts for internal combustion engines, ensuring that the camshaft and crankshaft move in time with each other. This synchronization is vital for optimal engine performance.

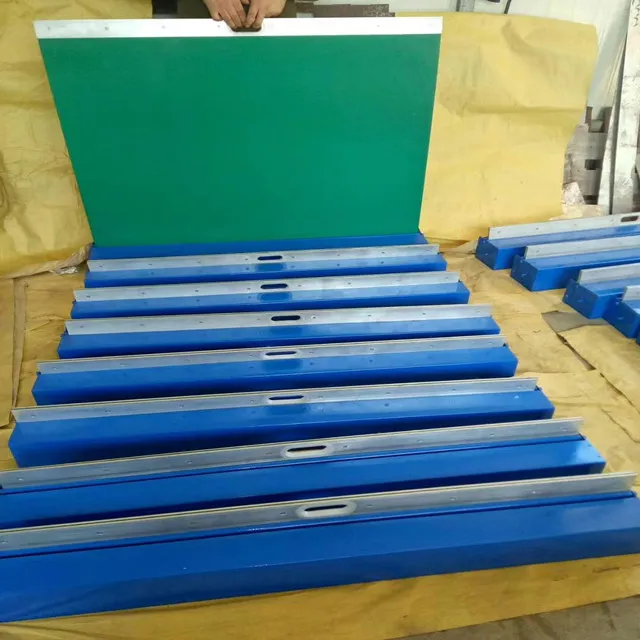

synchronous belt drive

In manufacturing, these systems are widely used in conveyor belts, where precise timing and positioning are essential for moving products along assembly lines. Additionally, they are found in 3D printers and CNC machines, where accurate positioning of the print head or milling tool directly affects the quality and precision of the final product.

Other applications include home appliances, like washing machines and dishwashers, where synchronous belts help in driving various components

. The versatility and reliability of synchronous belt drives make them an attractive choice across multiple sectors.Advantages of Synchronous Belt Drives

The advantages of synchronous belt drives are numerous. Firstly, their positive engagement eliminates slippage, allowing for high precision and consistent performance. This reliability leads to reduced wear and tear, thereby extending the lifespan of both the belts and the driven components.

Furthermore, synchronous belt drives operate quietly compared to chain drives or other mechanical systems. This factor can be especially beneficial in environments where noise reduction is crucial. Additionally, these systems require minimal maintenance, as they do not need frequent lubrication like chain drives, resulting in lower operational costs.

Lastly, with advancements in materials science, synchronous belts can now be manufactured to be incredibly lightweight, yet strong enough to handle significant loads. This development broadens their applicability in modern high-performance machines.

In conclusion, synchronous belt drives are a robust and efficient solution for motion transfer in various applications. Their unique design ensures precision, reliability, and low maintenance, making them indispensable in the fields of engineering and manufacturing. As technology continues to evolve, the potential applications and innovations surrounding synchronous belt drives are likely to expand even further.