Understanding the Benefits and Applications of Synchro Belts in Mechanical Systems

Understanding Synchronization with Synchro Belts

In the realm of mechanical engineering and industrial applications, synchro belts play a pivotal role in ensuring the smooth and efficient transmission of power between rotating shafts. These belts are specially designed to operate with synchronized pulleys, which allows for precise movement and torque transfer in various applications ranging from automotive engines to conveyor systems in manufacturing plants.

What is a Synchro Belt?

A synchro belt, also known as a timing belt, is a type of belt that features teeth on its inner surface. These teeth mesh with corresponding grooves on a set of pulleys, enabling the belt to maintain a precise relationship between the rotation of the driving and driven shafts. Unlike traditional V-belts, synchro belts eliminate slippage, ensuring that the power transmitted is consistent and reliable.

One of the most significant advantages of synchro belts is their ability to keep the timing of engine components in sync. For example, in an internal combustion engine, the synchro belt coordinates the rotation of the crankshaft with the camshaft, ensuring that the valves open and close at the correct times in relation to the position of the pistons. This synchronization is crucial for optimal engine performance and efficiency.

Advantages of Synchro Belts

1. Precision The primary advantage of synchro belts is their ability to deliver a precise motion. The teeth on the belt prevent slippage, which is crucial in applications where timing is everything. This precision is vital in various fields, including automotive, aerospace, robotics, and manufacturing.

2. Durability Synchro belts are made from high-quality materials such as rubber reinforced with polyester or fiberglass, which enhances their durability and longevity. They are designed to withstand harsh conditions, including temperature fluctuations and exposure to oils and chemicals, making them suitable for a broad range of environments.

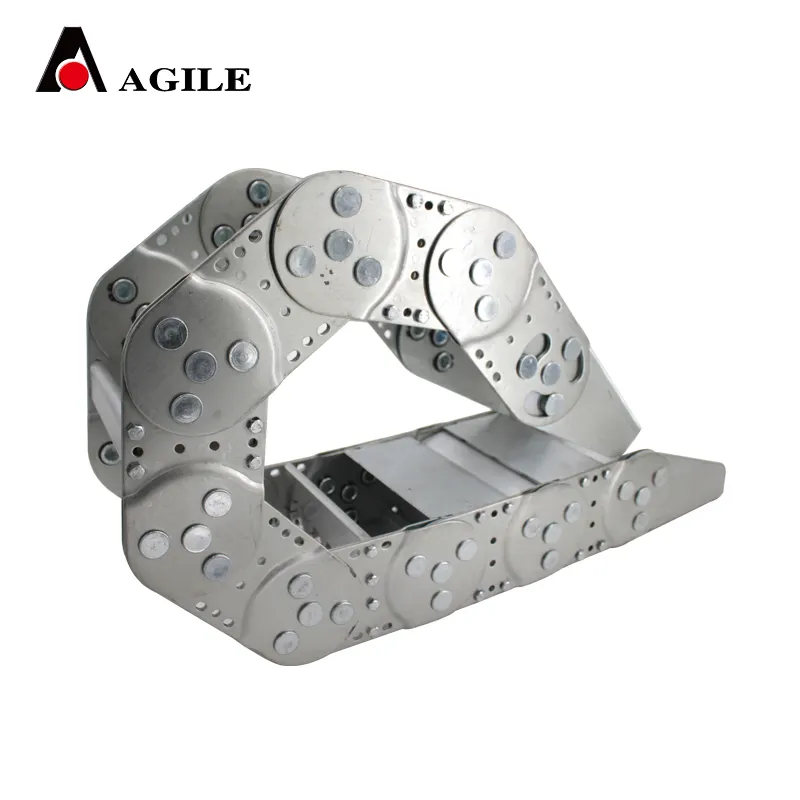

synchro belt

3. Low Maintenance Unlike chain drives, which require regular lubrication and tension adjustments, synchro belts are relatively low-maintenance. Once installed, they generally require minimal upkeep, making them a cost-effective solution for many applications.

4. Noise Reduction Synchro belts operate quieter than chain systems, which is a critical factor in applications where noise levels must be kept to a minimum, such as in office equipment and household appliances.

5. Compact Design The design of synchro belt systems allows for a more compact setup than traditional gear systems. This saves space and can lead to lighter machinery, which is particularly beneficial in automotive applications where weight reduction is crucial.

Applications of Synchro Belts

The applications of synchro belts are vast and varied. In the automotive industry, they are essential for timing mechanisms in engines, ensuring that various engine parts work in harmony. Additionally, they are used in gearboxes, water pumps, and accessory drives.

In industrial settings, synchro belts are employed in conveyor systems where precise movement is required to transport materials and products through production lines. Robotics and automation systems also regularly utilize synchro belts to ensure that servos and motors operate in sync, enhancing precision in tasks such as assembly and packaging.

Conclusion

In conclusion, synchro belts are an integral component in modern mechanical systems, offering numerous advantages that enhance performance, precision, and reliability. Their unique design allows for synchronous operation between components, making them invaluable in various industries. As technology continues to advance, the use of synchro belts is likely to expand further, driving innovation and efficiency in countless applications. Whether in automotive engineering, manufacturing, or robotics, synchro belts will remain at the forefront of mechanical design, ensuring that machines operate in perfect harmony.