sync belt

Understanding the Significance of Sync Belts in Modern Machinery

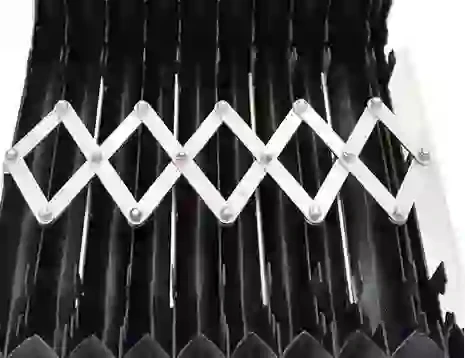

In the realm of machinery and automotive engineering, synchronization plays a pivotal role in ensuring that components operate seamlessly together. One of the key components that facilitate this synchronization is the sync belt. Also known as a timing belt, the sync belt is an essential part of internal combustion engines and various mechanical systems. It ensures that various parts of the engine, typically the crankshaft and camshaft, rotate in perfect unison.

The primary function of the sync belt is to keep the engine’s timing accurate. In a four-stroke internal combustion engine, the timing belt connects the crankshaft, which is responsible for turning the pistons, to the camshaft, which opens and closes the engine's valves. A precise synchronization between these two components is crucial because even a slight deviation can lead to catastrophic engine failure. Thus, the integrity of the sync belt is of utmost importance; if it wears out or breaks, it can result in severe engine damage and costly repairs.

Sync belts are typically made from a strong rubber material, reinforced with fibers to enhance durability and strength. Some advanced variations may include additional materials such as polyurethane or steel, providing increased resistance to wear and tear. This enhancement allows for greater efficiency and longevity, particularly in high-performance engines that operate under extreme conditions.

One of the key advantages of using a sync belt, as compared to traditional chain systems, is its quieter operation. Chains, while durable, can produce significant noise due to metal-on-metal contact. In contrast, sync belts provide a quieter alternative, which is especially valued in luxury vehicles and performance racing machines where noise reduction is paramount.

sync belt

Another beneficial feature of sync belts is their lightweight design. This attribute contributes to overall engine efficiency, allowing for better fuel economy and lower emissions. In today’s world, where environmental considerations are increasingly important, manufacturers are continually seeking ways to improve vehicle efficiency, and the use of timing belts plays a crucial part in this endeavor.

However, despite their advantages, sync belts are not without their downsides. They require regular maintenance and must be replaced periodically to prevent unforeseen failures. Most manufacturers recommend replacing the timing belt every 60,000 to 100,000 miles, depending on the vehicle's specific requirements. Ignoring these maintenance schedules can lead to disastrous outcomes, including complete engine failure, which can be both dangerous and financially debilitating for vehicle owners.

To ensure the longevity of sync belts, it is crucial to adhere to maintenance guidelines and to pay attention to signs of wear and tear. Common indicators that a belt may need replacement include unusual noises from the engine, slight slipping, or visible cracks on the belt surface. If any of these symptoms occur, it is advisable to consult a mechanic promptly to avert potential engine damage.

In conclusion, the sync belt stands as a testament to the intricate balance of engineering and the importance of routine maintenance in machine operation. As vehicles and machinery continue to evolve, the role of components like the sync belt will remain fundamental in ensuring efficiency, performance, and reliability. Understanding its function, benefits, and the need for proper care is essential for anyone involved in machinery maintenance or automotive engineering. By prioritizing these components, we can help foster a future where machinery operates smoothly and effectively, minimizing breakdowns and maximizing performance.