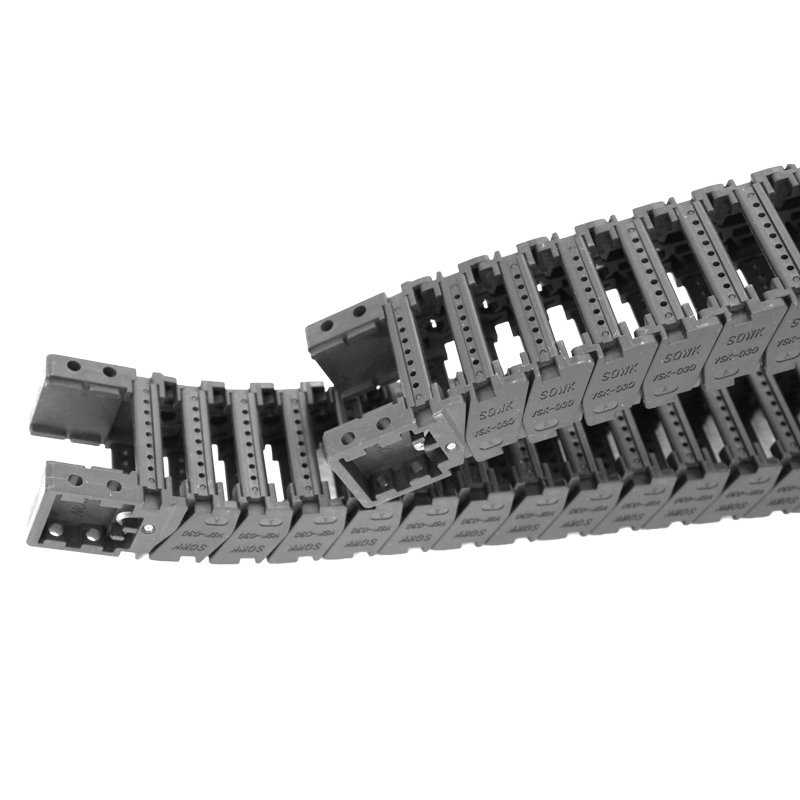

steel drag chain

Understanding Steel Drag Chains Essential Components for Modern Machinery

In an increasingly automated and industrialized world, the need for efficient material handling and management is more important than ever. One of the key components in achieving this efficiency is the steel drag chain, a machine element designed to guide and protect cables, hoses, and wires in various applications. This article explores the significance, design, and benefits of steel drag chains in contemporary machinery.

What is a Steel Drag Chain?

A steel drag chain is a durable and flexible system composed of interconnected links designed to carry and protect moving components, such as electrical cables, hydraulic hoses, and other utility lines. Commonly used in industrial settings, these chains are critical in scenarios where machinery operates in dynamic environments, ensuring that cables and hoses remain organized and free from wear and tear.

Applications in Industry

Steel drag chains are prevalent in numerous industries, including manufacturing, automotive, aerospace, and robotics. In manufacturing plants, for example, machines continually move and shift, requiring a robust and reliable solution to manage cables. Steel drag chains enhance safety by preventing entanglement and damage, which can lead to downtime and costly repairs.

Robotic systems, which often have complex wiring setups, benefit significantly from steel drag chains. They allow for smooth movements in multi-axis operations, ensuring that cables do not hinder the robotic arms' motions. Similarly, in automated assembly lines, drag chains streamline operations by maintaining a neat arrangement of utilities, reducing the risk of accidents caused by stray cables.

Advantages of Steel Drag Chains

steel drag chain

1. Durability As the name suggests, steel drag chains are built to withstand heavy loads and harsh operating conditions. Their construction from high-quality steel provides exceptional tensile strength, making them suitable for heavy machinery and rigorous environments.

2. Flexibility Steel drag chains are designed to bend and flex without compromising the integrity of the cables they hold. This flexibility allows for a wide range of movement, accommodating different types of machinery that may have varying motion patterns.

3. Protection One of the primary functions of steel drag chains is to protect cables and hoses from abrasion, cuts, and environmental factors such as dust, heat, and moisture. By enclosing these components, steel drag chains extend their lifespan and reduce maintenance needs.

4. Organization By keeping wires and hoses neatly arranged, steel drag chains help maintain an organized workspace, which is crucial for ease of maintenance and operational efficiency. This organization not only enhances safety but also facilitates quicker troubleshooting in case of malfunctions.

5. Easy Installation and Maintenance Many steel drag chains are designed for easy installation, with user-friendly features that simplify the setup process. Additionally, they often allow for quick replacement of individual links or cables, minimizing downtime during maintenance.

Conclusion

The steel drag chain is a vital component in modern machinery, playing a crucial role in ensuring efficient operations across various industries. Its combination of durability, flexibility, and protective capabilities makes it an indispensable tool for managing cables and hoses in dynamic environments. As industries continue to evolve and embrace automation, the importance of reliable systems like steel drag chains will only increase, paving the way for enhanced safety and productivity in the workplace. Whether you are in manufacturing, robotics, or any field requiring mobility and organization of critical components, adopting steel drag chains is a step towards innovation and operational excellence.