steel cable carrier

Understanding Steel Cable Carriers An Essential Component for Modern Machinery

In today's industrial landscape, efficiency and reliability are paramount. One of the unsung heroes of modern machinery that contributes significantly to these attributes is the steel cable carrier. These carriers, often referred to as cable trays or drag chains, are designed to enable the smooth and organized management of cables and hoses in a variety of environments. This article explores the importance, design, and applications of steel cable carriers in industrial settings.

What is a Steel Cable Carrier?

A steel cable carrier is a protective assembly used to manage and route cables and hoses in machinery. Constructed primarily from high-strength steel, these carriers are engineered to withstand the rigors of industrial environments, including extreme temperatures, dust, and mechanical wear and tear. Unlike plastic or nylon carriers, which can be effective in lighter applications, steel cable carriers offer enhanced durability and load-bearing capacity, making them ideal for heavy-duty uses.

Why Choose Steel?

The choice of steel as a primary material for cable carriers comes with several advantages

1. Durability and Strength Steel is renowned for its incredible tensile strength. Steel cable carriers can support heavier loads compared to their plastic counterparts, reducing the risk of failure or damage over time.

2. Heat Resistance In environments where temperature fluctuates or where hot machinery is involved, steel can withstand higher temperatures without deforming, ensuring that the cables remain protected.

3. Corrosion Resistance Many steel cable carriers come with special coatings that enhance their resistance to corrosion, particularly in environments where moisture or chemicals are present, ensuring longevity.

4. Safety By providing a structure for cables and hoses, steel cable carriers mitigate the risk of cables becoming entangled, tripping hazards being created, or machinery malfunctioning due to exposed or damaged wiring.

Design Considerations

The design of steel cable carriers involves several factors to ensure optimal performance

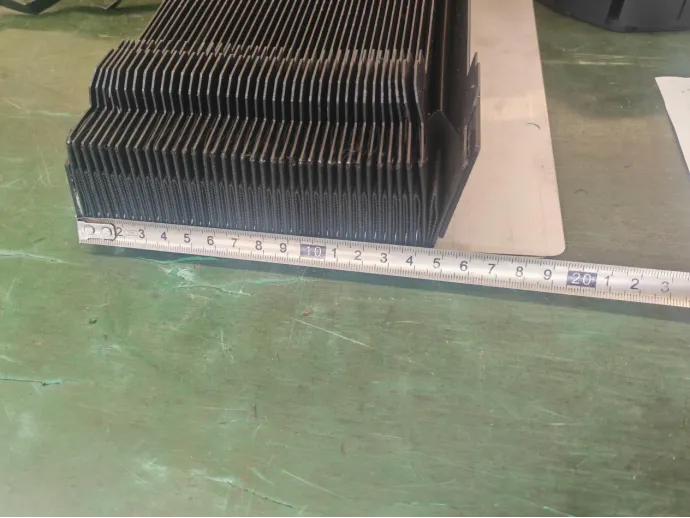

- Width and Height The dimensions of the carrier must match the size of the cables and hoses it is designed to carry. Insufficient space can lead to cable damage, while excessive space may lead to unnecessary movement.

steel cable carrier

- Bend Radius A proper bend radius must be accounted for, as cables have a minimum bend requirement to avoid damage. Ensuring the cable carrier maintains this radius is crucial for the longevity of the cables.

- Mounting and Support The installation process involves ensuring that the cable carrier is securely mounted and well-supported throughout its length to avoid sagging, which could lead to stress and breakage.

Applications

Steel cable carriers find application in a multitude of industries, including

1. Manufacturing In assembly lines where machines require power and command signals, these carriers smoothly deliver electrical power and data while preventing wear and tear.

2. Construction In construction sites, steel cable carriers provide the necessary support for temporary power solutions and can withstand the harsh conditions often found on-site.

3. Automotive In automotive production, steel cable carriers manage the complex networks of electrical systems in vehicles, ensuring precise alignment and protection.

4. Aerospace Given the critical nature of aerospace applications, cable carriers in this industry ensure that all electronic systems remain functional and safe in extreme conditions.

Maintenance and Best Practices

Maintaining steel cable carriers is relatively straightforward but essential for maximizing their lifespan. Regular inspections should be conducted to check for signs of wear, misalignment, or contamination of the cables. Also, lubrication of moving components can aid in reducing wear and tear. Proper installation techniques, such as ensuring correct alignment and using the appropriate hardware, are crucial in preventing future issues.

Conclusion

Steel cable carriers are vital components that underpin the functionality of modern industrial machinery. Their robustness, versatility, and ability to protect critical cables and hoses make them essential in various applications, from manufacturing to aerospace. As industries continue to evolve and demand greater efficiency, the application and innovation surrounding steel cable carriers will only grow, ensuring that they remain at the forefront of machinery management solutions. Whether investing in new systems or maintaining existing ones, recognizing the importance of these carriers is key to achieving optimal operational performance.