Durable Stainless Steel Drag Chains for Enhanced Industrial Applications and Efficiency

The Versatility of Stainless Steel Drag Chains in Modern Manufacturing

In the realm of modern manufacturing and automation, the importance of effective material handling cannot be overstated. Among the different solutions available, stainless steel drag chains have emerged as a vital component in various industries. These robust and reliable chains are designed to manage and protect cables, hoses, and other components in dynamic, moving applications. Their unique properties make them indispensable in settings where durability and resilience are paramount.

Stainless steel drag chains are particularly valued for their corrosion resistance. Unlike conventional chains made of other materials, stainless steel has excellent resistance to moisture, chemicals, and extreme temperatures, which makes it suitable for use in harsh environments. Industries such as food processing, pharmaceuticals, and even marine applications benefit significantly from this characteristic. In food processing, for instance, stainless steel drag chains can withstand frequent cleaning with high-pressure water and harsh detergents without losing structural integrity.

Another key advantage of stainless steel drag chains is their strength-to-weight ratio. Stainless steel is not only strong but also lightweight compared to other metals like iron or carbon steel. This allows manufacturers to design machinery and equipment that are both efficient and less energy-consuming. In automated systems, where precision and reliability are critical, the lightweight nature of these chains contributes to reduced wear and tear, ensuring a longer lifespan and lower maintenance costs.

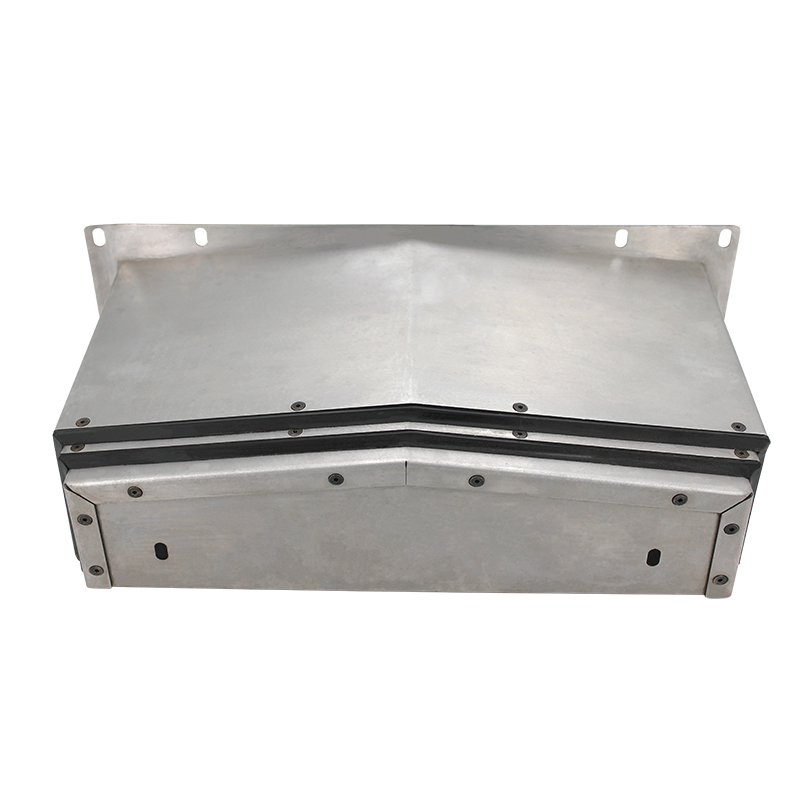

stainless steel drag chain

The design flexibility of stainless steel drag chains is also noteworthy. They can be customized to accommodate a variety of cable and hose sizes, ensuring that they can handle the specific needs of any operation. Additionally, manufacturers can tailor the chain’s geometry to fit unique applications, such as vertical movements, long distances, or high speeds. This adaptability is essential for businesses that require specific solutions to improve efficiency and safety.

Furthermore, stainless steel drag chains are designed with safety in mind. They help to prevent damage to cables and hoses by providing a protective conduit, significantly reducing the risk of entanglement or abrasion. This protective feature is crucial in high-speed environments where machinery is constantly in motion, as it keeps components organized and functioning optimally.

In conclusion, stainless steel drag chains are a critical innovation in the field of material handling and automation. Their corrosion resistance, lightweight design, customization options, and safety features collectively enhance their value across various industries. As businesses continue to seek ways to improve efficiency and reduce downtime, the adoption of stainless steel drag chains is likely to grow. With their ability to withstand the rigors of modern manufacturing processes, these chains will undoubtedly remain a staple in industrial applications for years to come.