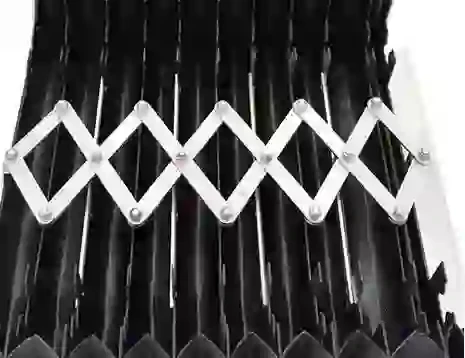

stainless steel drag chain

Understanding Stainless Steel Drag Chains A Comprehensive Guide

Stainless steel drag chains are essential components in various industrial applications, particularly those involving the transportation of cables and hoses in a safe and organized manner. This article delves into the features, benefits, applications, and considerations surrounding stainless steel drag chains.

What are Stainless Steel Drag Chains?

Stainless steel drag chains, also known as cable carriers, are designed to manage and protect moving cables, hoses, and pneumatic tubes in automated machinery. They work by providing a structured path that keeps cables organized and prevents tangling or snagging, which can lead to wear and tear or even equipment failure.

Features of Stainless Steel Drag Chains

1. Durability As the name suggests, stainless steel drag chains are made from high-quality stainless steel, which is known for its durability and resistance to corrosion. This makes them ideal for harsh environments where exposure to moisture, chemicals, and high temperatures is prevalent.

2. Flexibility and Customization These chains come in various sizes and designs, allowing manufacturers to customize drag chains according to specific needs. The flexibility of stainless steel also allows for smooth movements, minimizing the risk of cable damage.

3. Low Maintenance Given their robust construction, stainless steel drag chains require minimal maintenance. Users can expect a long service life, reducing downtime and maintenance costs associated with replacements.

4. Safety Features Many stainless steel drag chains incorporate safety features such as rounded edges and non-sharp components, reducing the risk of accidental injuries during operation.

Benefits of Using Stainless Steel Drag Chains

1. Enhanced Protection One of the most significant benefits of stainless steel drag chains is their ability to protect cables from external damage. By keeping cables neatly organized and out of harm’s way, these chains help ensure the longevity of electric and pneumatic systems.

2. Improved Efficiency By organizing cables and hoses, stainless steel drag chains streamline operations in automated machinery. This organization not only prevents mechanical failures due to tangled cables but also enhances the overall efficiency of production processes.

stainless steel drag chain

3. Versatility Stainless steel drag chains are used in a wide variety of applications, including robotics, CNC machines, material handling, and even in the automotive and aerospace industries. Their versatility makes them a valuable component in any industry that involves machinery and complex cable arrangements.

4. Cost-Effectiveness Although the initial investment in stainless steel drag chains may be higher than other materials, their long-term durability, low maintenance requirements, and ability to prevent equipment failure make them a cost-effective solution over time.

Applications of Stainless Steel Drag Chains

Stainless steel drag chains find a diverse range of applications. In the manufacturing sector, they are commonly used in conveyor systems, robotic arms, and CNC machining centers. In the automotive industry, they support assembly lines and other machinery where cable management is critical. Additionally, they are prevalent in medical equipment, food and beverage production, and waste treatment plants, where environmental resilience is crucial.

Considerations When Choosing Stainless Steel Drag Chains

When selecting stainless steel drag chains, several factors should be considered

1. Load Capacity Determine the weight and volume of cables or hoses to ensure the chosen drag chain can handle the load effectively.

2. Environment Assess the environment where the drag chain will be used (e.g., exposure to chemicals, temperature extremes) to select the appropriate grade of stainless steel.

3. Chain Size and Shape Consider the dimensions and design of the chain based on space availability and the specific requirements of the application.

4. Installation and Compatibility Ensure that the drag chain is compatible with existing machinery and that the installation process is straightforward.

Conclusion

Stainless steel drag chains are critical components in maintaining efficient and safe operations in various industries. Their durability, flexibility, and ability to protect cables make them an invaluable asset for any facility. By understanding their features, benefits, and applications, businesses can make informed decisions when integrating these essential parts into their operations, ultimately enhancing productivity and reducing costs.