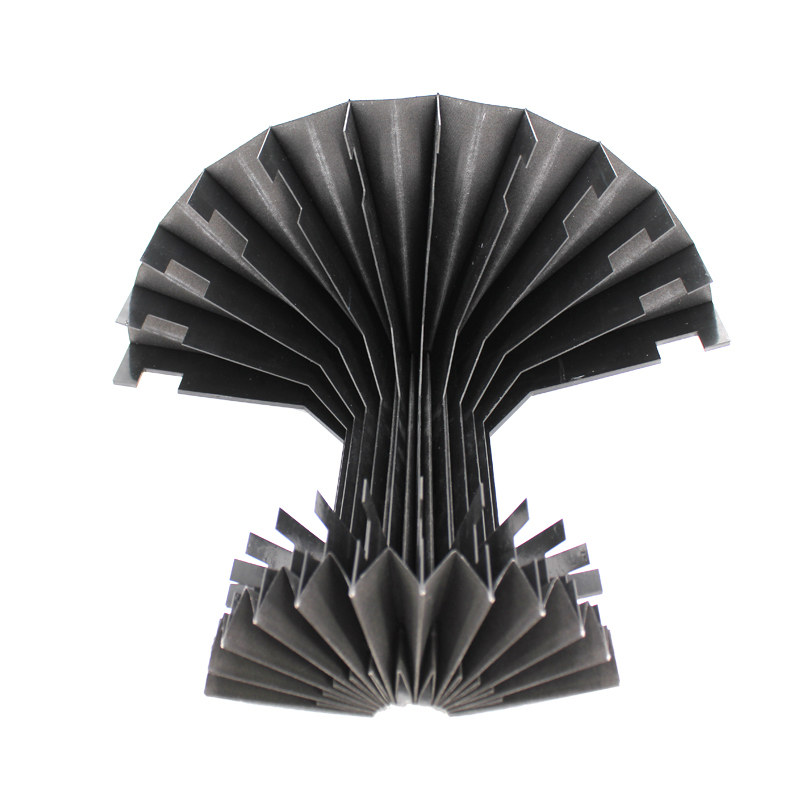

stainless steel drag chain

The Benefits and Applications of Stainless Steel Drag Chains

In today's fast-paced industrial environment, the efficiency of machinery and equipment plays a crucial role in enhancing productivity and ensuring smooth operations. One often-overlooked component that contributes significantly to this efficiency is the drag chain, particularly made of stainless steel. Known for its durability, corrosion resistance, and versatility, stainless steel drag chains are becoming increasingly popular across various industries.

What is a Drag Chain?

A drag chain, also known as an energy chain or cable carrier, is a device used to guide and protect flexible cables and hoses in machinery and equipment. It allows for the organized movement of wires and tubes, preventing tangling and wear that can lead to failure and increased maintenance costs. Drag chains are particularly essential in situations where equipment undergoes repetitive movement, such as in robotic arms, CNC machines, and conveyor systems.

Why Stainless Steel?

Stainless steel, an alloy primarily composed of iron, carbon, and chromium, is known for its outstanding mechanical properties and resistance to oxidation and corrosion. The use of stainless steel in drag chains provides several advantages

1. Corrosion Resistance Stainless steel is inherently resistant to rust and corrosion, making it ideal for environments where exposure to moisture, chemicals, and other corrosive elements is a concern. Industries such as food processing, pharmaceuticals, and marine applications benefit greatly from using stainless steel drag chains.

2. Durability and Strength Stainless steel drag chains are exceptionally strong and can withstand high loads. This strength ensures that they can support heavy machinery and equipment, extending the lifespan of both the chains and the cables they protect.

3. Temperature Resistance Stainless steel can maintain its integrity in extreme temperature conditions, which is particularly beneficial in industries where temperature fluctuations are common, such as metalworking and plastics manufacturing.

stainless steel drag chain

4. Hygienic Properties In industries like food and beverage, the hygienic properties of stainless steel are paramount. The smooth surface of stainless steel drag chains can be easily cleaned and maintained, helping to prevent contamination.

Applications of Stainless Steel Drag Chains

The versatility of stainless steel drag chains makes them suitable for a wide range of applications across various sectors

- Manufacturing and Automation In automated production lines, stainless steel drag chains guide power and control cables, ensuring that they remain protected while allowing for continuous movement.

- Robotics Robots used in manufacturing frequently encounter repetitive motions. Stainless steel drag chains provide the necessary flexibility and protection for their cables, enhancing both performance and durability.

- CNC Machines These machines often involve complex movements and require robust cable management systems. Stainless steel drag chains help to keep the necessary electronic connections safe and organized.

- Conveyor Systems In warehousing and logistics, stainless steel drag chains are used to manage cables in conveyor systems, improving efficiency and reliability in transporting goods.

Conclusion

Stainless steel drag chains offer a reliable solution for organizations seeking to enhance their operational efficiency while minimizing maintenance and downtime. Their combination of strength, corrosion resistance, and versatility makes them an invaluable asset across diverse industries. As technology evolves, the demand for such durable and efficient components will continue to grow, ensuring that stainless steel drag chains remain a cornerstone of modern machinery and equipment design. Therefore, investing in high-quality stainless steel drag chains is not only a smart choice but a necessary step toward achieving operational excellence.