stainless steel cable carrier

Understanding Stainless Steel Cable Carriers

In the world of industrial machinery and robotics, the effective management of cables is a critical aspect that can significantly influence the performance, safety, and longevity of equipment. One of the most reliable solutions for cable management is the stainless steel cable carrier, commonly used in various applications, from CNC machines to automated assembly lines. This article delves into the advantages and features of stainless steel cable carriers, shedding light on why they are a preferred choice in many industries.

What is a Stainless Steel Cable Carrier?

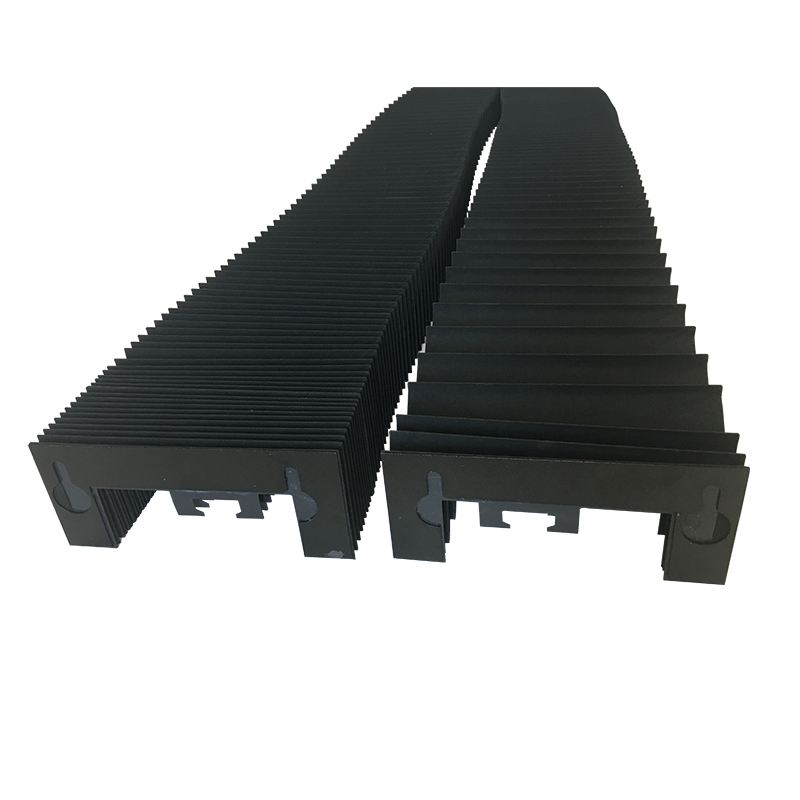

A stainless steel cable carrier, also known as a drag chain or cable chain, is a flexible structure designed to guide and protect cables and hoses in motion. Unlike traditional plastic carriers, stainless steel carriers offer enhanced durability, making them resistant to a variety of harsh environmental conditions, including extreme temperatures, chemicals, and humidity.

Advantages of Stainless Steel Cable Carriers

1. Durability and Longevity Stainless steel is known for its robust properties, including high tensile strength and resistance to corrosion. In industries where equipment is exposed to moisture, chemicals, or extreme temperatures, stainless steel cable carriers exhibit superior longevity compared to their plastic counterparts.

2. Hygienic Properties In sectors such as food processing, pharmaceuticals, and healthcare, hygiene is paramount. Stainless steel carriers do not harbor bacteria and can be easily cleaned, making them ideal for environments where sanitation is crucial. Their smooth surfaces prevent the accumulation of dirt and other contaminants.

stainless steel cable carrier

3. Flexibility and Design Stainless steel cable carriers come in various designs to accommodate different cable sizes and configurations. They are engineered to allow bent and flexible movement, which is essential in applications like robotics and automated machinery. This flexibility reduces wear on cables and hoses, extending their lifespan.

4. Heat Resistance Stainless steel can withstand higher temperatures than many plastic carriers, making it suitable for high-temperature applications like furnace equipment and machinery that generates a significant amount of heat. This attribute helps prevent the risk of melting or deforming under stress.

5. Strength and Load Capacity Stainless steel carriers can handle heavier loads compared to plastic variants. This characteristic makes them ideal for industries that require robust solutions to support multiple cables and hoses simultaneously without compromising on performance or safety.

Applications of Stainless Steel Cable Carriers

Stainless steel cable carriers are used across various industries, including manufacturing, automotive, aerospace, and energy sectors. They are commonly found in CNC machines, robotics, conveyor systems, and other automated equipment. Moreover, in offshore and marine applications, their resistance to corrosion and ability to operate under harsh conditions make them the preferred choice.

Conclusion

Stainless steel cable carriers stand out as a vital component in the realm of industrial machinery. With their unmatched durability, hygienic properties, and versatile design, they help ensure efficient cable management in diverse applications. As industries continue to evolve and face new challenges, the demand for reliable, high-performance solutions like stainless steel cable carriers is likely to grow. Investing in quality cable management systems is not just a matter of operational efficiency; it is essential for ensuring safety and longevity in any industrial setup.