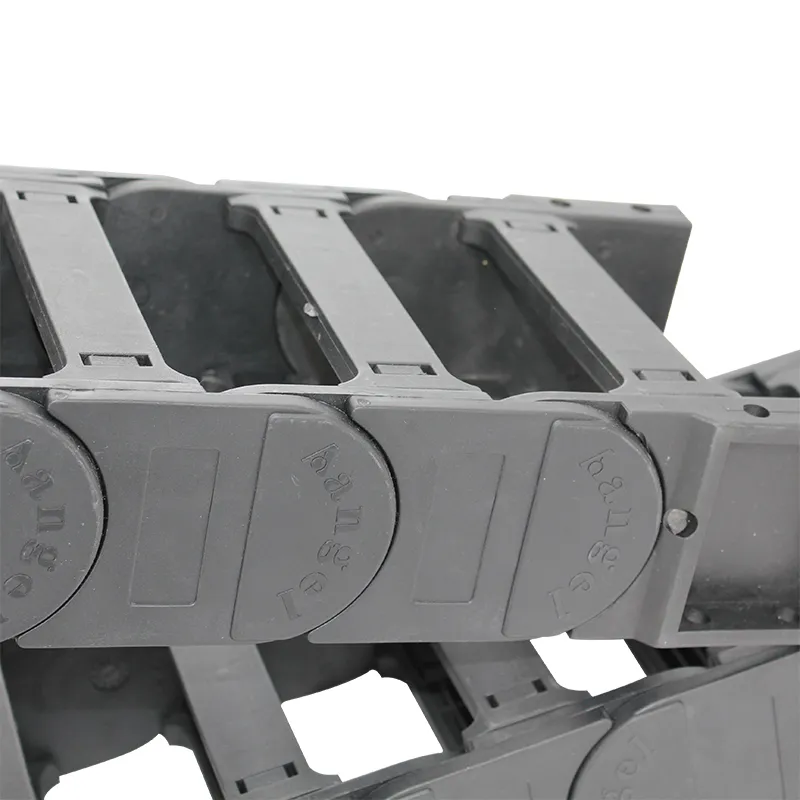

ss drag chain

Understanding SS Drag Chains An Essential Component for Cable Management

In the realm of modern engineering and manufacturing, effective cable management is crucial for ensuring efficient operations and safety. Among various solutions available, SS (stainless steel) drag chains have emerged as an invaluable component for protecting and organizing cables, hoses, and other flexible connections in a myriad of industrial applications. This article delves into the characteristics, benefits, uses, and maintenance of stainless steel drag chains.

What Are SS Drag Chains?

SS drag chains, also known as cable carriers or energy chains, are systems designed to guide and protect moving cables and hoses in machinery and equipment. Constructed from high-quality stainless steel, these chains are engineered to withstand demanding environments, resist corrosion, and provide a long service life. Their design allows for flexible routing of cables, minimizing stress and wear while ensuring smooth and reliable operation.

Key Benefits of SS Drag Chains

1. Durability One of the standout features of stainless steel drag chains is their robustness. The intrinsic properties of stainless steel make these chains resistant to rust, corrosion, and wear, making them suitable for extreme environments, such as those found in food processing plants, chemical facilities, and marine applications.

2. Versatility SS drag chains can accommodate a wide range of cable types and sizes, from power cables to delicate signal wires. This versatility enables their application in various industries, including automotive, aerospace, robotics, and manufacturing.

3. Safety and Protection By enclosing cables and hoses, drag chains protect them from hazards such as abrasion, crushing, and environmental factors. This protection not only enhances the longevity of the cables but also reduces the risk of electrical hazards, supporting overall workplace safety.

4. Space Efficiency These chains are designed to optimize space in machinery and work areas. Their organized structure prevents tangling and clutter, allowing for more efficient use of space and easier access to components during maintenance.

5. Sleek Aesthetic Stainless steel offers a modern appearance that can contribute to the overall aesthetics of machinery and equipment. This quality is especially valuable in settings where equipment visibility is critical, such as in customer-facing environments.

Applications of SS Drag Chains

ss drag chain

While SS drag chains find use across various sectors, they are particularly beneficial in applications where movement is frequent and environmental conditions are harsh. Common applications include

- Robotics In robotic arms and automated machinery, drag chains facilitate the smooth movement of cables and hoses, ensuring uninterrupted operation and reducing wear.

- Machine Tools SS drag chains are employed in CNC machines and lathes, helping to organize and protect the numerous cables used for power, data transmission, and fluid delivery.

- Conveyor Systems In conveyor lines, drag chains keep power and control cables neatly organized, preventing interference with the movement of goods.

- Automotive Assembly In automotive manufacturing, drag chains manage the extensive wiring and cable runs that are crucial for assembly line efficiency.

Maintenance of SS Drag Chains

Maintaining stainless steel drag chains is essential to ensure their longevity and performance. Regular inspections for wear, damage, and proper alignment should be conducted. It is also important to clean the chains periodically to remove dust, debris, and any contaminants that may cause wear. Lubrication of moving parts is necessary to minimize friction and enhance operational efficiency.

Additionally, operators should ensure that the cables within the drag chains are properly laid out with adequate allowance for movement. Tight bends or excessive tension can lead to premature wear and potential cable failure.

Conclusion

SS drag chains are a critical component in modern industrial applications, providing an efficient and reliable solution for cable management. Their durability, versatility, and protective features make them invaluable in a wide range of settings. By carefully selecting and maintaining stainless steel drag chains, businesses can enhance operational efficiency, ensure safety, and extend the lifespan of their electrical systems. As industries continue to evolve, the role of drag chains in facilitating seamless operations will only grow, underscoring their importance in the world of engineering and manufacturing.