split wire tubing

The Versatility and Importance of Split Wire Tubing

In the world of electrical installation and cable management, split wire tubing stands out as an essential component that enhances both functionality and safety. This flexible protective conduit provides a reliable solution for organizing, shielding, and insulating wires, ensuring long-lasting performance in various applications.

What is Split Wire Tubing?

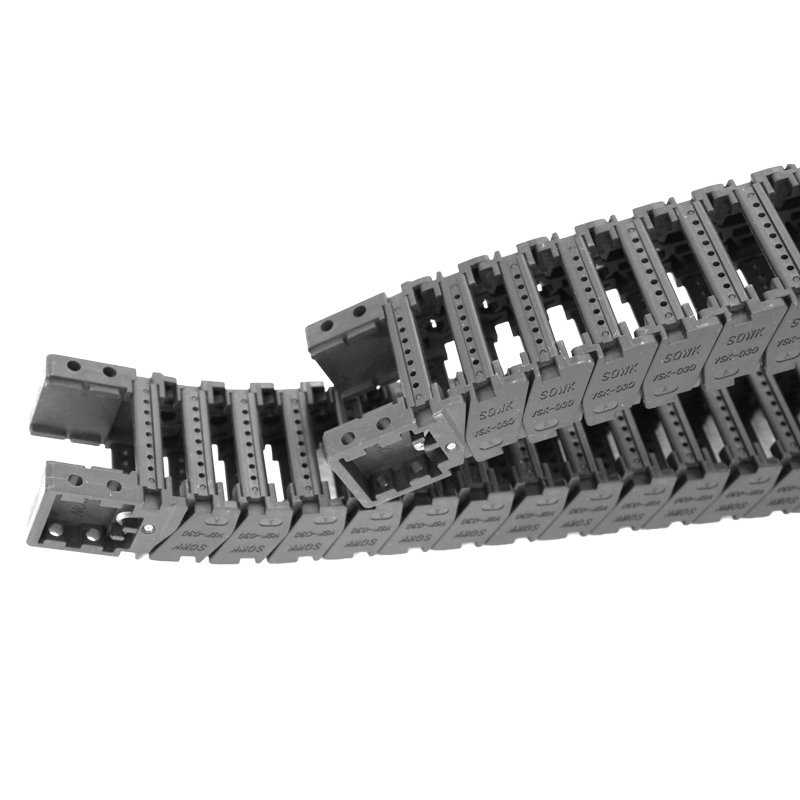

Split wire tubing, often made from materials like polyethylene or polyvinyl chloride (PVC), is a flexible tube that can easily accommodate wires and cables. Its unique design features a longitudinal slit along one side, allowing it to be easily opened and closed around existing wires. This split functionality distinguishes it from traditional unsplit tubing, making it an ideal choice for retrofitting or upgrading electrical systems without the need to disconnect or remove installed cables.

Key Benefits

1. Ease of Installation The split design allows for quick and simple installation. Users can effortlessly slide the tubing over existing wires and secure it in place, reducing installation time and labor costs.

2. Protection Against Wear and Tear Split wire tubing provides a protective barrier against abrasion, chemicals, and environmental factors. This shielding helps prevent damage to the wires, which could lead to electrical failures or safety hazards.

split wire tubing

3. Organized Management By grouping multiple wires together, split wire tubing promotes a tidy and organized appearance. This is particularly beneficial in both commercial and residential settings, where neatness can enhance aesthetic appeal and make troubleshooting easier.

4. Flexibility and Versatility Available in various sizes and colors, split wire tubing can accommodate a wide range of wire gauges. This versatility makes it suitable for multiple applications, including automotive wiring, home theater installations, and industrial machinery.

5. Cost-Effectiveness Given its durability and protective qualities, split wire tubing serves as a cost-effective solution in the long run. By preventing wire damage and reducing the need for repairs, it can lead to significant savings on maintenance and replacement costs.

Applications

Split wire tubing is widely used across various industries. In automotive applications, it protects wire harnesses from abrasion and heat, ensuring reliable operation in challenging environments. In residential settings, it can be utilized to manage cables for electronic devices, home theaters, and computer systems, providing a cleaner appearance and reducing trip hazards. Additionally, in industrial environments, it shields wires in machinery and equipment, safeguarding them from potential damage caused by mechanical movements or chemical exposure.

Conclusion

Split wire tubing is more than just a protective conduit; it is a practical solution that enhances the safety, organization, and longevity of electrical installations. With its ease of use, protective qualities, and versatility, it is a valuable asset in many applications. Whether you are a DIY enthusiast looking to tidy up your home cinema setup or a professional electrician seeking efficient wiring solutions, split wire tubing is undoubtedly a worthy consideration. Its role in modern electrical systems underscores the importance of quality materials in the pursuit of safety and efficiency. As technology continues to advance, so too will the materials and designs of split wire tubing, ensuring its relevance for years to come.