split wire loom

The Benefits and Uses of Split Wire Loom

In the world of wire management and organization, split wire loom has emerged as a favored solution for countless applications across various industries. This versatile product not only aids in protecting wires and cables but also enhances the aesthetic appeal of wiring systems. In this article, we will explore the benefits, applications, and installation methods related to split wire loom.

What is Split Wire Loom?

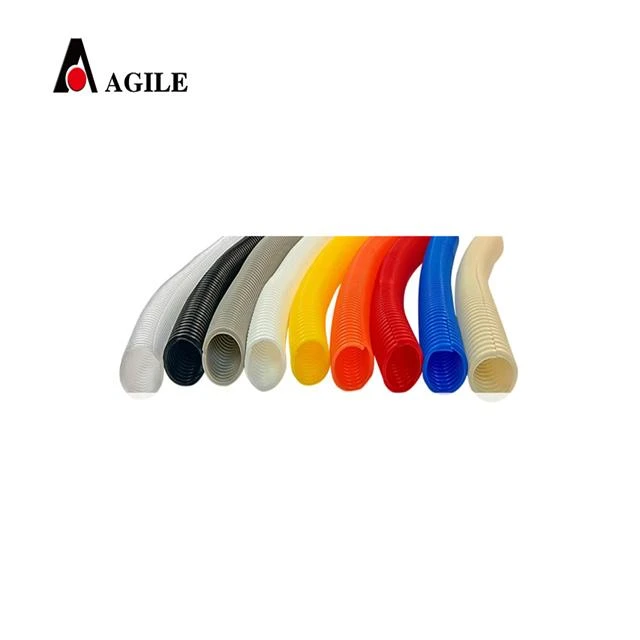

Split wire loom is a type of plastic tubing that is designed to encase and organize wires. It is commonly made from polyethylene or other durable plastics that can withstand a range of environmental conditions. The split design allows for easy insertion of multiple wires, enabling users to manage complex wiring systems without the need for additional connectors or tools.

Protection from Environmental Factors

One of the primary benefits of using split wire loom is its protective capabilities. Wires and cables are often subjected to various environmental factors, including moisture, heat, oil, and abrasion. This exposure can lead to wear and tear, ultimately jeopardizing the functionality and safety of the electrical systems. Split wire loom acts as a protective barrier, shielding wires from potential damage and extending their lifespan.

Organization and Aesthetics

In addition to protection, split wire loom is instrumental in organizing wiring systems. By grouping wires together, it reduces clutter and confusion, making it easier to identify individual cables when maintenance is required. This organization is particularly crucial in environments like automotive applications, industrial machinery, and home wiring systems, where multiple wires run in close proximity.

split wire loom

Furthermore, using split wire loom can enhance the overall appearance of wiring installations. Neat, organized wires not only look better but can also improve safety by minimizing the risk of accidental disconnection or damage caused by entangled cables.

Versatile Applications

Split wire loom is not limited to a specific industry; its versatility makes it suitable for a wide range of applications. In the automotive industry, it is commonly used to wrap wires in engine compartments, protecting them from heat and friction. In household wiring, it can be applied to organization within walls or exposed areas, maintaining a tidy look. Additionally, in industrial settings, split wire loom is invaluable for managing complex wiring in machinery and control panels.

Moreover, with the rise of technology in home automation and smart devices, the need for organized and protected wiring has never been more critical. Split wire loom fits seamlessly into modern wiring projects, ensuring both functionality and safety.

Easy to Install

Installing split wire loom is a straightforward process, making it accessible even for those with minimal technical experience. To begin, measure the length of wire that needs protection and cut the split loom to the desired length. Afterward, simply place the wires into the loom and seal the ends if necessary, either with zip ties or tape. The split design allows for easy access, enabling users to add or remove wires without hassle.

Conclusion

In summary, split wire loom is an essential component in effective wire management, offering protection, organization, and aesthetic benefits across numerous applications. Its ease of use, durability, and versatility make it an indispensable tool for both professionals and DIY enthusiasts alike. Whether for automotive, industrial, or residential applications, incorporating split wire loom into your wiring system can significantly improve safety and efficiency. As technology continues to advance and wiring becomes more complex, the importance of effective wire management solutions like split wire loom will undoubtedly remain a priority in various fields. Embracing this handy tool can lead to cleaner, safer, and more efficient wiring systems for all settings.