Advantages of Split Sleeve Tubing in Oil and Gas Applications for Enhanced Performance and Safety

The Importance of Split Sleeve Tubing in Modern Engineering Applications

In the field of engineering and construction, the efficiency and effectiveness of various processes depend largely on the materials and methods used. One such innovation that has gained ground is split sleeve tubing, a component that plays a pivotal role in various applications, particularly in the oil and gas, construction, and manufacturing industries. This article delves into the concept of split sleeve tubing, its benefits, and its applications.

Understanding Split Sleeve Tubing

Split sleeve tubing is a type of tubular material with a longitudinal split along its length. This design allows the sleeve to expand and contract, providing adaptability in different applications. Typically, the tubing is manufactured from durable materials such as stainless steel, carbon steel, or specialized alloys, making it suitable for high-pressure and high-temperature environments.

The split design allows for easier installation and maintenance. Unlike traditional tubing systems, which require precise alignment and welding, split sleeve tubing can be easily positioned and locked in place, significantly reducing installation time and costs. This feature makes it a go-to choice for many engineers and construction professionals.

Benefits of Split Sleeve Tubing

1. Versatility One of the main advantages of split sleeve tubing is its versatility. It can be used in various applications, including but not limited to casing repairs in oil wells, structural reinforcements in construction, and as protective covers for cables and pipes. The ability to adapt to different shapes and sizes makes it an invaluable tool in many industries.

2. Cost-Effectiveness The installation process for split sleeve tubing is generally simpler and quicker than for conventional tubing, which translates into reduced labor costs. Moreover, the durability of the materials used in manufacturing split sleeves often results in lower maintenance and replacement costs over time.

3. Enhanced Safety In industries where safety is paramount, such as oil and gas, split sleeve tubing offers increased protection against leaks and mechanical failures. Its robust design provides a secure layer of protection for underlying structures, minimizing the risk of accidents that could endanger workers or the environment.

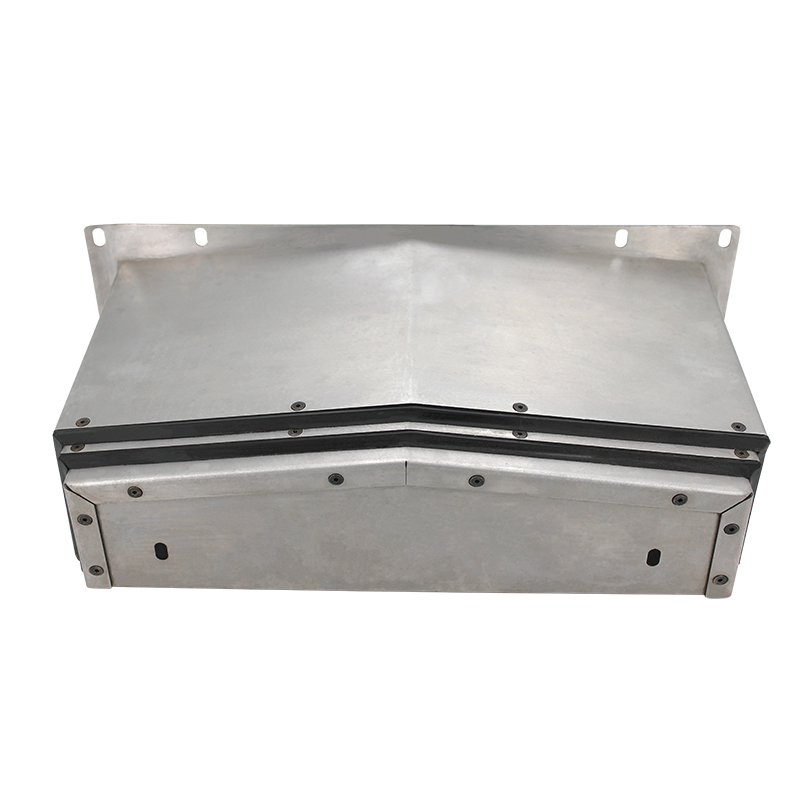

split sleeve tubing

4. Improved Performance Split sleeve tubing enhances the performance of systems by ensuring a tight seal and providing support during high-pressure operations. This ability to maintain structural integrity under load makes split sleeves essential in critical applications where failure is not an option.

5. Ease of Replacement In situations where tubing needs to be replaced, split sleeve designs allow for quick and straightforward removal without the need for complicated tools or techniques. This feature is particularly important in maintenance-heavy sectors, where downtime can lead to significant financial losses.

Applications of Split Sleeve Tubing

The application of split sleeve tubing spans across various sectors. In the oil and gas industry, it is primarily used for casing repairs in wells, where the sleeve can be expanded to cover damaged sections effectively. This process provides a reliable solution for extending the life of well casings and ensuring safe extraction operations.

In the construction field, split sleeve tubing is often employed for reinforcing structures. It can be used in conjunction with rebar to create composite systems that improve the tensile strength and durability of concrete. This application is particularly useful in seismic zones where buildings are susceptible to ground movement.

Additionally, in the field of electrical engineering, split sleeve tubing serves as a protective conduit for cables, ensuring that they are safeguarded against physical damage and environmental factors.

Conclusion

In conclusion, split sleeve tubing represents a significant advancement in engineering materials and techniques. Its versatility, cost-effectiveness, enhanced safety features, improved performance, and ease of replacement make it a valuable asset across various industries. As technology continues to advance, it is likely that the applications and benefits of split sleeve tubing will only expand, further solidifying its role in modern engineering and construction practices. Investing in innovative solutions such as split sleeve tubing can lead to improved efficiencies and safety, ultimately contributing to the success of engineering projects worldwide.