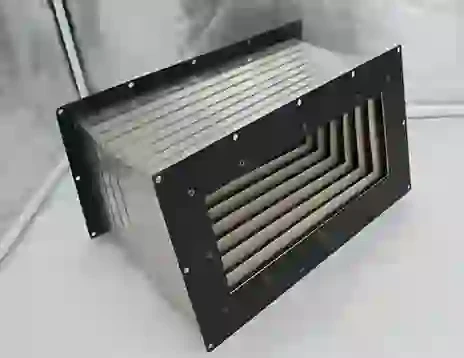

split sleeve tubing

Understanding Split Sleeve Tubing A Comprehensive Overview

In the world of oil and gas production, innovative technologies are continually being developed to enhance efficiency and safety. One such advancement is the split sleeve tubing system, an integral part of modern well completion and intervention strategies. This article delves into the purpose, functionality, benefits, and application of split sleeve tubing, highlighting its significance in the industry.

What is Split Sleeve Tubing?

Split sleeve tubing is a specialized type of completion device used in oil and gas wells. It consists of a pipe that is divided into two halves along its length, designed to be actuated to open or close perforations in the wellbore. This design allows operators to selectively control fluid flow from the reservoir into the well, making it a vital component in enhancing production efficiency.

The split sleeve itself is typically made of high-grade materials that are capable of withstanding the harsh conditions found in well environments, including high pressures and corrosive fluids. The technology behind split sleeve tubing enables operators to manage multiple zones within a single wellbore, thereby optimizing production while minimizing environmental impact.

How Does It Work?

The operation of a split sleeve tubing system involves the use of hydraulic pressure or mechanical methods to manipulate the split sleeve. When the sleeve is in its closed position, the well is isolated, preventing the flow of fluids. By applying pressure, the sleeve is pushed open, allowing hydrocarbons to flow into the wellbore from the surrounding formation.

This mechanism provides operators with the flexibility to open and close zones as needed. Moreover, the split sleeve technology allows for the perforation of multiple zones in a single trip, reducing the amount of time and resources required for well completion.

Benefits of Split Sleeve Tubing

1. Enhanced Production Control The ability to selectively control fluid flow from different zones allows operators to maximize hydrocarbon recovery while minimizing waste. Operators can target specific zones based on their production potential, leading to improved overall efficiency.

split sleeve tubing

2. Reduced Operational Costs Traditional methods of achieving similar results often involve multiple trips to the wellbore, which can be time-consuming and expensive. With split sleeve tubing, multiple zones can be accessed in a single trip, significantly reducing operational costs and downtime.

3. Minimized Environmental Impact By enabling targeted production and reducing the need for excessive intervention trips, split sleeve tubing systems contribute to a lower environmental footprint. Operators can optimize resource extraction without unnecessary disturbance to surrounding areas.

4. Enhanced Well Integrity The robust materials and advanced design of split sleeve tubing contribute to improved well integrity. This ensures that the well can withstand the high pressures and corrosive environments often encountered in production phases.

5. Ease of Intervention In cases where workovers or maintenance are needed, split sleeve systems can be easily accessed and manipulated, allowing for quick interventions that can enhance well performance without extensive infrastructure or equipment modifications.

Application in the Industry

Split sleeve tubing technology is applicable in various stages of oil and gas production. It is commonly used in horizontal wells, where multiple zones may need to be accessed. Additionally, the technology is suitable for re-completion projects where operators seek to enhance production from existing wells.

For offshore operations, the compact nature of split sleeve systems makes them particularly advantageous, allowing for efficient use of space and resources in challenging environments. As the industry continues to explore unconventional resources and deeper reservoirs, the flexibility provided by split sleeve tubing systems becomes increasingly vital.

Conclusion

Split sleeve tubing represents a remarkable advancement in well completion technology, offering a reliable, efficient, and environmentally conscious solution for managing hydrocarbon production. As the oil and gas industry evolves to meet modern challenges, the implementation of innovative technologies like split sleeve tubing will play a crucial role in ensuring sustainable and profitable operations. Through enhanced control, reduced costs, and improved well integrity, split sleeve tubing is poised to remain a pivotal asset in the energy sector.