Innovative Techniques for Dividing Loom Wires Effectively in Textile Production

The Significance of Split Loom Wire in Modern Electrical Installations

In the world of electrical installations and cable management, the term split loom wire often surfaces as a vital component for ensuring both efficiency and safety. This choice of tubing is instrumental in safeguarding wiring systems from potential damage while also facilitating neat organization. This article explores what split loom wire is, its uses, advantages, and the best practices for effective implementation.

What is Split Loom Wire?

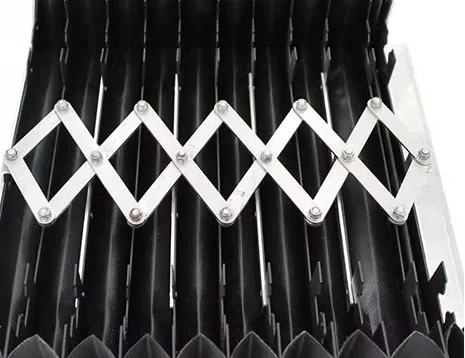

Split loom wire is a lightweight, flexible plastic tubing, typically made from polyethylene or PVC, designed to protect electrical wires and cables. Its unique feature is the longitudinal split along its length, which allows it to easily encase multiple wires and cables without requiring any additional fasteners. This design not only simplifies installation but also provides a degree of versatility in handling different cable gauges and configurations.

Uses of Split Loom Wire

The primary use of split loom wire is to provide protection to electrical wires from abrasion, dirt, moisture, and chemicals. It serves as a protective layer for wiring in various applications, including automotive, marine, and industrial settings. In automotive applications, for instance, split loom tubing prevents wires from chafing against sharp edges, which could lead to shorts or damage. Similarly, in the industrial context, it shields cables in machinery and equipment from the rigors of day-to-day operations.

Beyond protection, split loom wire is also instrumental in organizing and bundling cables. In environments where numerous wires are in play, such as server rooms, workshops, or even home theaters, using split loom can significantly reduce clutter. By grouping cables together, it enhances the aesthetic appeal of the installation and makes maintenance and troubleshooting substantially more straightforward.

Advantages of Split Loom Wire

1. Protection The primary advantage of split loom tubing is its ability to protect wires from physical damage. This durability helps prolong the lifespan of cables, reducing the frequency of replacements and repairs.

2. Flexibility Split loom wire is highly flexible, allowing it to easily adapt to various bends and shapes. This flexibility is particularly beneficial in tight spaces or when routing cables around corners.

3. Ease of Installation Installing split loom wire is quick and straightforward. There’s no need for special tools; simply cut to the desired length, split open the tubing, and insert the wires. This ease of use can save valuable time, especially in large-scale installations.

split loom wire

4. Cost-effective Compared to other cable management solutions, split loom wire is generally more affordable. Its cost-effectiveness, combined with its protective qualities, makes it a popular choice among both professionals and DIY enthusiasts.

5. Chemical Resistance Many types of split loom tubing exhibit resistance to chemicals, making them suitable for use in environments where exposure to hydrocarbon-based substances is possible.

Best Practices for Implementation

While split loom wire offers numerous advantages, effectively utilizing it requires adherence to certain best practices

- Choose the Right Size It’s essential to select the correct diameter of split loom tubing that can accommodate the number and size of cables being bundled. A size too small may not fit properly, while one that is too large can lead to unmanageable slack.

- Proper Cutting When cutting split loom tubing, ensure the ends are clean and smooth. This prevents any jagged edges from potentially damaging the wires during installation.

- Securing the Loom In certain applications, it may be beneficial to secure the split loom in place using zip ties or other fasteners to prevent it from shifting, especially in high-vibration environments.

- Regular Inspection Regularly inspect the split loom tubing for any signs of wear or damage. Early detection of any issues can prevent larger problems in the future.

Conclusion

In summary, split loom wire plays an integral role in modern electrical installations by providing protection and organization to wiring systems. Its flexibility, ease of installation, and cost-effectiveness make it a popular choice for professionals and DIYers alike. By adhering to best practices, users can maximize the benefits of split loom wire, ensuring their electrical systems are not only functional but also secure and aesthetically pleasing. As technology advances, the need for efficient cable management will continue to rise, and split loom wire will likely remain a staple in the toolbox of electricians everywhere.