split loom tubing sizes

Understanding Split Loom Tubing Sizes A Comprehensive Guide

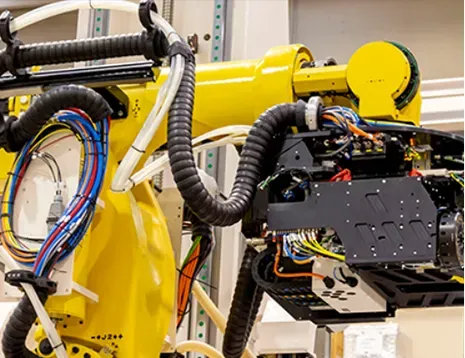

Split loom tubing has become an essential component in various industries, particularly in electrical and automotive applications. This flexible, protective tubing is designed to organize, shield, and manage wires and cables, ensuring their longevity and safety. Among the key considerations when selecting split loom tubing is the size, which can significantly affect the effectiveness of its application. This article delves into the various sizes of split loom tubing, their applications, and how to choose the right one for your needs.

What is Split Loom Tubing?

Split loom tubing is a type of conduit made from plastic, typically polyethylene or polypropylene, that features a longitudinal slit running its length. This design allows for easy installation over existing cables and wires without needing to disconnect them. Split loom tubing protects against abrasion, dirt, moisture, and other environmental factors, making it suitable for both indoor and outdoor applications.

Common Sizes of Split Loom Tubing

Split loom tubing comes in various sizes to accommodate different wire gauges and applications. The sizing is generally measured by the inner diameter (ID) of the tubing. Here are some common sizes available on the market

1. 1/4 inch (6mm) - This is ideal for small wire harnesses, such as those found in automotive applications for low-voltage systems. 2. 3/8 inch (10mm) - Often used for standard electrical wiring, this size can accommodate a small bundle of wires or cables without being overly bulky.

3. 1/2 inch (13mm) - A common size for residential and commercial wiring, providing enough space for several wires to run together safely.

split loom tubing sizes

5. 1 inch (25mm) and larger - Suitable for industrial applications or where heavy-duty wiring is required, such as in large machinery or commercial vehicles.

Choosing the Right Size

Selecting the right size of split loom tubing is crucial for optimal performance. Here are some factors to consider

1. Wire Gauge The size of the wires you intend to group together will determine the required diameter of the tubing. Always check the wire gauge to ensure it fits comfortably within the selected size.

2. Number of Wires Consider how many cables you need to bundle. If you have multiple wires, it’s often wise to choose a larger size to prevent overcrowding, which can lead to wear and heat build-up.

3. Environmental Factors If the application will be exposed to harsh conditions, consider thicker-walled tubing for additional protection.

4. Flexibility versus Rigidity The expected movement of the cables can influence size choice. A flexible installation may require a size that allows for expansion and movement, while a static installation may benefit from a more rigid option.

Conclusion

In summary, split loom tubing is a versatile solution for managing and protecting wires in various applications. Its effectiveness largely depends on selecting the appropriate size based on wire gauge, the number of cables, and environmental conditions. By understanding the different sizes available and key considerations for selection, you can ensure the longevity of your wiring systems while maintaining safety and organization. Whether you're working on a small DIY project or a large industrial installation, choosing the right split loom tubing is an essential step in your wiring management process.