split loom for wiring

Understanding the Split Loom for Wiring A Comprehensive Guide

When it comes to electrical and automotive wiring, organization and protection are key components for ensuring a safe and effective installation. One of the most utilized tools for this purpose is the split loom tubing. This article explores split loom tubing in detail, its applications, benefits, and best practices for using it in your wiring projects.

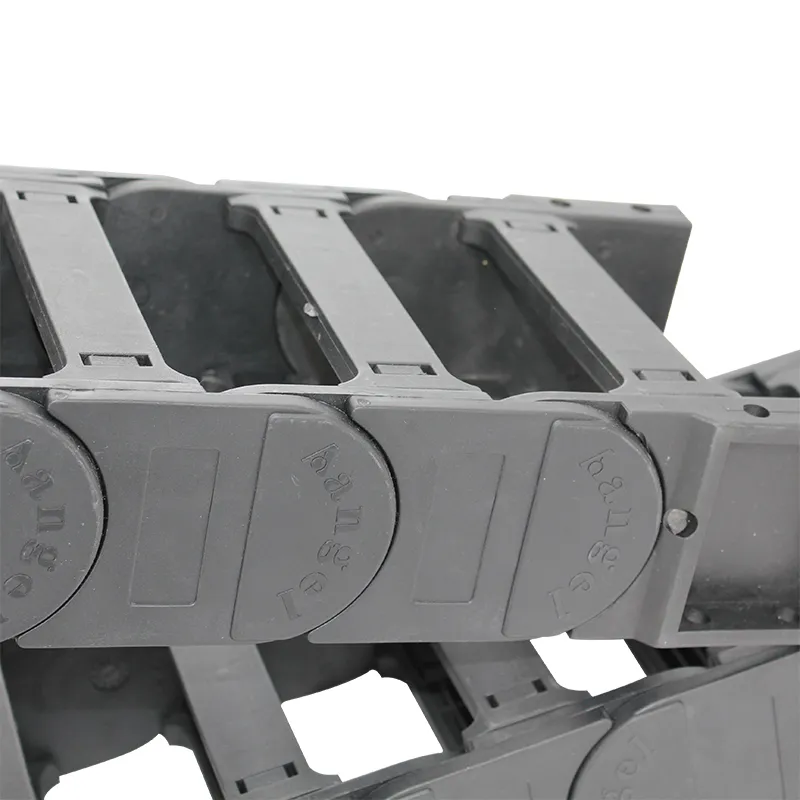

What is Split Loom Tubing?

Split loom tubing is a type of protective conduit for wiring made from high-quality plastic, typically polyethylene or polypropylene. The tubing is characterized by its split design, which allows for easy insertion and removal of wires without the need for additional connectors or tools. It comes in various sizes and colors, making it a versatile option for numerous applications.

Applications of Split Loom Tubing

1. Automotive Wiring In the automotive industry, split loom tubing is extensively used to protect wires and cables from abrasion, moisture, and other environmental factors. It helps maintain the integrity of wiring harnesses against the rigors of engine vibrations, temperature fluctuations, and exposure to chemicals.

2. Home Electrical Projects Homeowners and electricians often use split loom tubing for various DIY and professional electrical projects. It provides an efficient way to bundle and protect wires running through walls, ceilings, and basements. By keeping wires organized, split loom also minimizes the risk of electrical shorts and damage.

3. Industrial Applications In industrial settings, machinery and equipment often face tough working conditions. Split loom tubing is employed to protect wires in factories and manufacturing plants, ensuring they withstand wear and tear while providing optimal performance.

4. Telecommunications Telecommunications infrastructure relies heavily on organized wiring setups. Split loom tubing is frequently used in this sector to manage cables, providing both protection and ease of access for maintenance.

Benefits of Using Split Loom Tubing

1. Protection The primary benefit of split loom tubing is its ability to shield wires from physical damage, including abrasion, cuts, and environmental hazards. This is vital to prolonging the lifespan of electrical systems.

split loom for wiring

2. Organization By bundling cables together, split loom tubing simplifies the management of wires. An organized wiring system is not only easier to troubleshoot but also provides a professional aesthetic.

3. Flexibility The split design of the tubing allows for easy modification of wiring setups. Users can add or remove wires without having to dismantle the entire system, making it ideal for dynamic environments.

4. Ease of Installation Installing split loom tubing requires minimal tools and expertise, making it accessible for both professionals and DIY enthusiasts. This ease of use is a significant advantage for quick repairs and installations.

Best Practices for Using Split Loom Tubing

1. Choose the Right Size It is crucial to select a split loom size that comfortably accommodates the number of wires you plan to bundle. Too tight, and it may cause wire damage; too loose, and it may not provide adequate protection.

2. Cutting When cutting split loom tubing, use sharp scissors or a rotary cutter to ensure clean edges. This will prevent fraying and ensure a snug fit around the wires.

3. End Sealing To keep dirt, moisture, and debris out of the tubing, consider using end seals or caps on each section of split loom tubing. This added layer of protection can greatly enhance the longevity of your wiring system.

4. Regular Inspections Regularly inspect the condition of your split loom tubing, especially in applications subject to heavy usage or exposure to harsh elements. Look for signs of wear and replace sections when necessary.

Conclusion

Split loom tubing is an essential tool for anyone involved in wiring projects, whether in automotive, industrial, or residential settings. Its protective qualities, organizational advantages, and ease of use make it a preferred choice for many professionals and DIY enthusiasts alike. By following best practices and utilizing split loom tubing effectively, you can ensure that your wiring remains safe, organized, and efficient for years to come.