Exploring Split Loom Tubing for Efficient Wiring Management and Protection

Understanding Split Loom for Wiring A Comprehensive Guide

When it comes to organizing and protecting electrical wires, split loom is a versatile and highly effective solution. This tubing, made from durable materials, serves to contain multiple wires neatly while safeguarding them from physical damage and environmental factors. In this article, we’ll delve into the various aspects of split loom, including its significance, installation process, and advantages.

What is Split Loom?

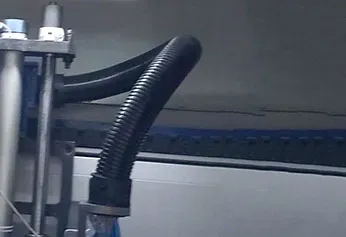

Split loom is a type of conduit that provides a protective cover for electrical wires. It is typically made from plastic, though variations exist in materials such as nylon or polyethylene. The defining characteristic of split loom is its split design, which allows for easy insertion and removal of wires. This feature makes it incredibly convenient for applications that require frequent adjustments or replacements of wiring.

Splitting along one side, the loom can expand to accommodate multiple wires, making it suitable for various sizes and configurations. It usually comes in a variety of diameters, ranging from small to large, ensuring that there is a suitable option for nearly any wiring project.

Significance of Using Split Loom

The use of split loom is significant for several reasons. Firstly, it helps to organize wires, reducing clutter and confusion. Disorganized wiring can not only look unsightly but may also pose safety risks, including potential electrical shorts or breaks. By using split loom, wires can be bundled together neatly, making it easier to trace connections and troubleshoot issues.

split loom for wiring

Secondly, split loom provides a layer of protection for wires against abrasions, cuts, and environmental factors such as moisture and UV rays. This can be particularly important in automotive applications, where wires are often exposed to extreme conditions. The protective nature of split loom extends the life of the wiring, thereby reducing the need for frequent repairs or replacements.

Installation Process

Installing split loom is relatively straightforward. Begin by measuring the length of the wires you wish to cover. Then, select the appropriate diameter of split loom tubing that will comfortably fit around your wires without being overly tight.

To install, simply place the wires into the split loom and press down to secure them. If working with a longer length of wiring, it may be beneficial to use additional supports or clips to hold the loom in place. For the best results, ensure that the split is oriented in such a way that allows for easy access to the wires if modifications are necessary in the future.

Advantages of Split Loom

There are several advantages to using split loom for wiring. Firstly, it is cost-effective; a relatively small investment can yield significant returns in the form of enhanced wire protection and organization. Moreover, the installation process is user-friendly and does not typically require specialized tools or skills, making it accessible for both home and professional use.

In conclusion, split loom serves as an invaluable tool for anyone working with electrical wiring. Its ability to organize, protect, and streamline the wiring process makes it a top choice for myriad applications, from home projects to automotive wiring. By understanding and utilizing this reliable conduit, you can ensure that your wiring remains organized and safeguarded for years to come.