split loom 1 2

Exploring the Concept of Split Loom in Modern Applications

In the realm of industrial design and practical applications, the term split loom often emerges as a significant element, particularly in the context of electrical wiring and cable management. This essential tool has become indispensable for various industries that prioritize organization, safety, and efficiency in their operations. In this article, we will delve into the concept of split loom, its applications, benefits, and the reasons behind its growing popularity.

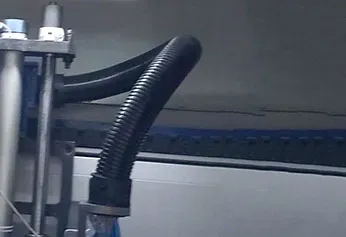

Split loom, essentially a flexible tubing system, is designed to protect and bundle wires and cables. Its name comes from the fact that it is split down one side, allowing users to easily insert wires without having to thread them through entirely. This unique feature makes it far more versatile and user-friendly than traditional cable management systems. The split loom is typically made from durable materials such as polyethylene, which offers excellent resistance to abrasion, chemicals, and environmental factors.

Exploring the Concept of Split Loom in Modern Applications

Beyond the automotive sector, split loom also finds extensive use in home and office environments. For instance, as homes increasingly adopt smart technology, the demand for organized and protected wiring systems grows. Homeowners often use split loom to manage wires from televisions, sound systems, and other electronic devices. This not only maintains a tidy living space but also reduces the risk of electrical hazards posed by loose or damaged wires.

split loom 1 2

Additionally, in commercial settings, businesses benefit from implementing split loom for similar reasons. It helps maintain a safe workplace by minimizing tripping hazards and preventing equipment malfunctions caused by exposed wires. In factories and warehouses, where heavy machinery is in operation, split loom tubing becomes crucial in ensuring that wiring remains protected from wear and tear, ultimately enhancing operational efficiency.

The benefits of using split loom extend beyond mere organization. By utilizing this protective system, individuals and businesses can significantly decrease maintenance costs associated with damaged wiring. Preventing wear and tear on cables can prolong the lifespan of electrical systems, reducing the need for frequent repairs or replacements. Furthermore, split loom can contribute to improved safety measures. Exposed wires can pose serious risks, such as electrical shocks or fires; thus, by covering them, the likelihood of such incidents can be minimized.

In an era where sustainability and environmental awareness are becoming increasingly vital, split loom also offers eco-friendly advantages. Many split loom products are manufactured from recyclable materials, allowing for responsible disposal when they reach the end of their lifecycle. Also, by prolonging the life of electrical components, split loom helps reduce waste and contributes to a more sustainable approach to technology management.

In conclusion, the split loom represents an essential component in the world of cable management and electrical wiring protection. Its flexibility, user-friendly design, and protective qualities make it invaluable across various sectors, including automotive, residential, and commercial industries. As technology continues to advance and our reliance on electrical systems grows, the importance of effective cable management solutions like split loom will undoubtedly rise. By adopting this innovative tool, we not only improve safety and organization but also contribute to greater sustainability in our practices. As such, understanding and utilizing split loom should be a priority for anyone involved in electrical work, whether professionally or at home.