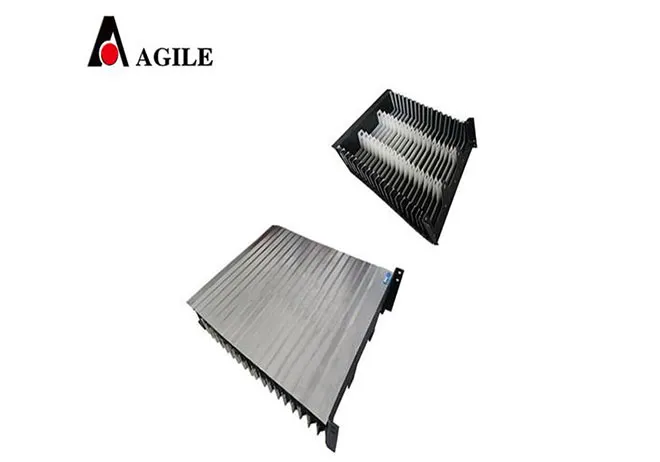

split flex wire loom

Exploring Split Flex Wire Loom Benefits and Applications

When it comes to protecting and organizing wiring systems in various applications, split flex wire loom is a go-to solution for many industries. Its versatility, durability, and ease of use have made it an essential component in everything from automotive to industrial settings. In this article, we will explore what split flex wire loom is, its benefits, and its various applications.

What is Split Flex Wire Loom?

Split flex wire loom is a type of tubing made from high-density polyethylene (HDPE) that is designed to encase and protect electrical wires. Unlike traditional wire loom tubing, split flex wire loom features a longitudinal slit along its length, allowing users to easily insert or remove wires without disconnecting the entire assembly. This characteristic makes it particularly convenient for applications where wires need to be added or removed frequently.

Benefits of Split Flex Wire Loom

1. Easy Installation and Modification The primary advantage of split flex wire loom is its user-friendly design. The split allows for quick installation over existing cables, making it a time-saving solution for technicians and engineers. Additionally, if a worker needs to add or remove wires, they can do so without having to remove the entire loom, facilitating easier modifications.

2. Durability and Protection Split flex wire loom is designed to withstand various environmental factors. It provides excellent protection against abrasion, impacts, and chemicals, extending the lifespan of the wires enclosed within it. This durability is crucial in harsh environments, such as automotive engines or industrial machinery, where wires are exposed to heat, oil, and other potentially damaging substances.

3. Cable Management This type of wire loom helps in organizing and managing multiple wires. By grouping wires together neatly, split flex wire loom reduces the risk of tangling and confusion, especially in industries where multiple cables are common. Improved organization not only enhances efficiency but also makes troubleshooting and maintenance easier.

4. Aesthetic Appeal In addition to its practical benefits, split flex wire loom can also enhance the aesthetic quality of electrical installations. The sleek and uniform appearance of wrapped wires is visually appealing, making it a popular choice in consumer electronics and custom installations.

split flex wire loom

5. Flame Resistance Many split flex wire loom products are manufactured with flame-retardant materials, providing an added layer of safety in installations where fire hazards are a concern. This feature meets various industry safety standards, making them suitable for use in a variety of applications.

Applications of Split Flex Wire Loom

1. Automotive Wiring One of the most common uses of split flex wire loom is in automotive wiring. From high-performance sports cars to everyday vehicles, protecting wiring harnesses from heat and abrasion is critical. Split flex wire loom ensures that wires remain secure and protected, whether in the engine compartment or along the vehicle’s chassis.

2. Industrial Equipment In industrial settings, machinery and equipment often operate in high-stress conditions. Split flex wire loom safeguards electrical connections from the hazards of heavy machinery, chemicals, and moving parts. Industries such as manufacturing, oil and gas, and construction frequently use this product.

3. Home and HVAC Systems For residential applications, split flex wire loom can be used in home wiring and HVAC systems. It protects low-voltage cables, ensuring they remain organized and safe from wear over time. Whether it’s managing wires for your home entertainment system or securing connections in heating and cooling systems, split flex wire loom provides a reliable solution.

4. Consumer Electronics Many manufacturers of consumer electronics utilize split flex wire loom for organizing internal wiring in devices like computers, televisions, and appliances. Its neatness and protective qualities contribute to the overall quality and reliability of these products.

Conclusion

In conclusion, split flex wire loom proves to be an invaluable tool for protecting and managing electrical wiring across a wide range of applications. Its ease of use, durability, and aesthetic appeal make it a preferred choice in industries such as automotive, manufacturing, and consumer electronics. As technology continues to advance, the role of split flex wire loom in ensuring the integrity and longevity of wiring systems will only grow in importance. Whether you are a technician, engineer, or a DIY enthusiast, incorporating split flex wire loom into your projects will undoubtedly yield significant benefits.