split flex tubing white

The Versatility of Split Flex Tubing in Modern Applications

In a world where flexibility and efficiency are paramount, split flex tubing has emerged as a crucial component in various industries. This innovative product is particularly favored for its ability to protect, organize, and route cables and hoses effectively. Available in various sizes and colors, including the ever-popular white variant, split flex tubing is adaptable to numerous applications ranging from automotive to telecommunications.

What is Split Flex Tubing?

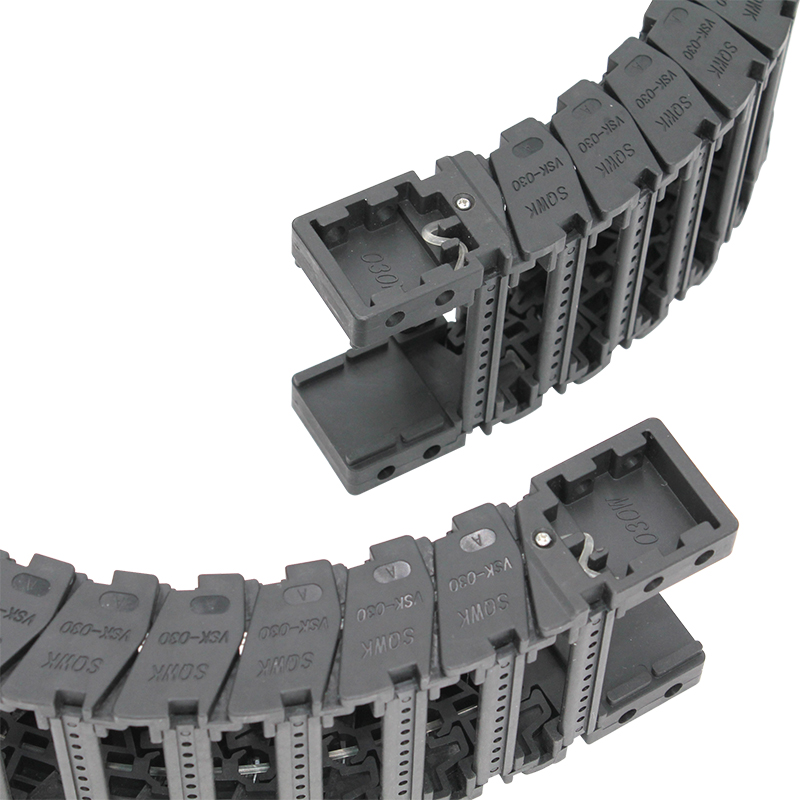

Split flex tubing, often made from durable polyethylene or nylon, is characterized by its unique design, which features a slit running along its length. This design allows users to easily insert and remove cables or hoses without needing to disassemble any fittings or connectors. The tubing comes in different diameters, making it suitable for various cable sizes, ensuring that it can accommodate the equipment used in any specific application.

White split flex tubing, in particular, serves multiple purposes. Its color not only offers a clean and aesthetic appearance, but it also aids in visibility, making it easier to identify cables in a crowded space. This can be especially important in environments where safety and efficiency are top priorities, such as in industrial settings or data centers.

Key Benefits of Split Flex Tubing

1. Protection One of the primary purposes of using split flex tubing is to provide protection for cables and hoses. It shields them from abrasion, moisture, chemicals, and the elements. This is particularly crucial in industries such as automotive and aerospace, where exposure to harsh conditions could lead to significant damage and costly repairs.

split flex tubing white

2. Organization In any large-scale operation, keeping cables organized is essential. Split flex tubing helps in neatly bundling multiple cables together, reducing clutter and preventing tangles. This not only simplifies installation but also makes future maintenance considerably easier.

3. Flexibility The ability to insert and withdraw cables as needed gives split flex tubing an edge over traditional tubing solutions. This flexibility allows users to adapt to changing requirements, which is particularly advantageous in fast-paced environments where modifications are common.

4. Cost-Effectiveness By prolonging the lifespan of cables and reducing downtime for repairs, split flex tubing can lead to significant cost savings over time. Its durability ensures that replacement and maintenance costs are minimized.

Applications Across Industries

Split flex tubing has found its place in diverse fields, including automotive, telecommunications, and electronics. In the automotive sector, it's used to cover and protect wiring harnesses, shielding them from engine heat and external damage. In telecommunications, it ensures that the myriad of cables used in data transmission are organized and protected from physical interference. The electronics industry also benefits significantly, as split flex tubing provides a clean and efficient solution for bundling internal wires in devices ranging from computers to household appliances.

Conclusion

The rise of split flex tubing, particularly the white variant, highlights the importance of adaptive and protective solutions in our increasingly connected world. Its ability to organize, protect, and facilitate cable management makes it an indispensable tool in various sectors. As industries continue to innovate and evolve, split flex tubing will undoubtedly remain a key player in promoting efficiency, safety, and organization in modern applications. Its unique design and myriad benefits represent not just a practical solution, but a testament to the ingenuity of contemporary materials and engineering.