split loom tubing sizes

Understanding Split Loom Tubing Sizes

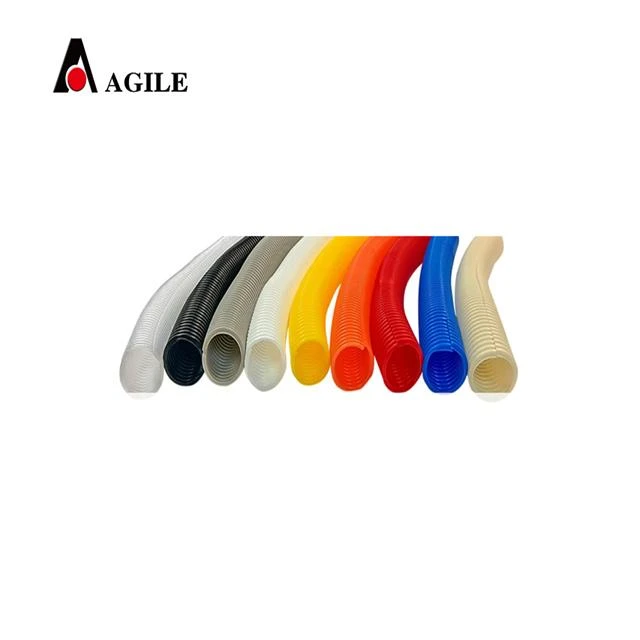

In the realm of cable management and protection, split loom tubing has gained significant popularity due to its versatility and ease of use. This robust yet flexible tubing serves as an effective shield against abrasion, moisture, and various environmental factors that can compromise the integrity of electrical wires and cables. One vital aspect of selecting split loom tubing is understanding its sizes, which can significantly impact both performance and application.

Understanding Split Loom Tubing Sizes

When choosing the right size, it’s crucial to consider the type and number of wires that will be bundled together. For instance, a smaller diameter split loom may suffice for a single wire or smaller gauge wires, whereas larger bundles or thicker wires may require a wider diameter to ensure a proper fit without overcrowding. This not only assists in maintaining optimal flexibility but also minimizes the potential for damage to the wiring.

split loom tubing sizes

Another important consideration is the length of the tubing. Split loom tubing is typically sold by the foot and can be easily cut to desired lengths, allowing for bespoke solutions that meet specific needs. This makes installation not only straightforward but also customizable, providing flexibility for different project requirements.

Moreover, the split design of the tubing allows for quick installation and easy access to individual wires without the need to remove the entire bundle. This feature is especially beneficial in maintenance and repair scenarios, where rapid access to wiring may be necessary.

Environmental factors also play a role in size selection. For instance, an application that operates in extreme temperatures or exposure to chemicals may require robust options that can withstand such conditions. Thus, alongside size, it is essential to consider the material composition of the split loom tubing—common materials include polyethylene and nylon, which both offer varying degrees of durability and flexibility.

In conclusion, selecting the appropriate split loom tubing size is fundamental to effective cable management. By understanding the various diameters available and the specific needs of your application, you can ensure that your wiring remains well-protected and organized. Whether for personal or professional use, the right tubing makes all the difference in extending the lifespan and performance of your electrical systems.