slit corrugated sleeving

Understanding Slit Corrugated Sleeving Applications and Benefits

In the world of industrial applications and electrical systems, the need for effective protection of cables and wires is paramount. One solution that has gained popularity over the years is slit corrugated sleeving. This innovative product offers a range of benefits that make it ideal for various applications, from automotive to electronics and beyond.

What is Slit Corrugated Sleeving?

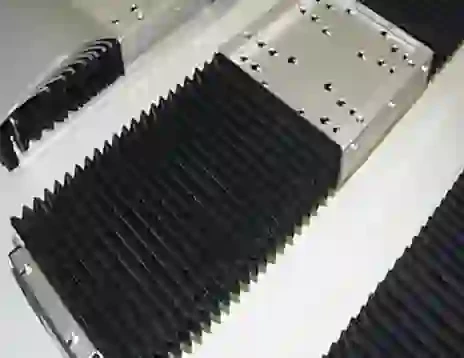

Slit corrugated sleeving is a type of protective tubing that is engineered to safeguard cables and wires from damage due to abrasion, cutting, and environmental factors. The structure of the sleeving is characterized by its corrugated design, which allows for flexibility and adaptability. The slit refers to a longitudinal cut along the length of the sleeve, enabling easy installation over existing cables without the need for disconnecting or dismantling them.

The sleeving is typically made from materials like polyethylene, PVC, or nylon, which are known for their durability and resistance to harsh conditions. The corrugated form enhances its strength and gives it the ability to expand and contract, accommodating cable movement and vibration.

Applications of Slit Corrugated Sleeving

The versatility of slit corrugated sleeving makes it suitable for a wide array of applications

1. Automotive Industry In vehicles, wires and cables are constantly exposed to heat, moisture, and friction. Slit corrugated sleeving helps protect these components from wear and tear, promoting a longer lifespan and preventing malfunctions.

2. Electronics In the electronics sector, where delicate wiring is commonplace, this sleeving offers a reliable barrier against physical damage and electromagnetic interference (EMI). Its lightweight nature does not add significant bulk to the assemblies, preserving the overall design integrity of electronic devices.

3. Industrial Machinery Machinery often operates in environments where cables are susceptible to abrasion and exposure to chemicals. The robust materials used in slit corrugated sleeving provide an effective shield against such threats, ensuring machinery operates smoothly and safely.

slit corrugated sleeving

4. Telecommunications In the telecommunications industry, protecting sensitive wiring from environmental factors is crucial. Slit corrugated sleeving offers the necessary protection while allowing for easy access and maintenance of the cables inside.

Benefits of Using Slit Corrugated Sleeving

The advantages of using slit corrugated sleeving extend beyond mere protection

- Ease of Installation Thanks to the slit design, installation is straightforward, saving time and reducing labor costs. It can be easily wrapped around existing cables, making it a preferred choice for retrofitting protection.

- Flexibility and Adaptability The corrugated structure allows the sleeving to bend and conform to various shapes, accommodating a range of cable sizes and configurations without compromising on protection.

- Cost-Effectiveness By preventing damage to wires, slit corrugated sleeving can reduce the frequency and costs of repairs and replacements. This makes it a cost-effective solution for businesses in the long run.

- Enhanced Safety By shielding cables from damage, it also helps prevent electrical hazards and fire risks, promoting safer operating conditions in both industrial and residential environments.

Conclusion

Slit corrugated sleeving is a vital component in the protection of cables and wires across various industries. Its unique design and material properties provide not only protection from potential damage but also flexibility and ease of installation, making it an ideal choice for many applications. As technology continues to advance, the demand for effective cable management solutions like slit corrugated sleeving will only continue to grow, ensuring the safety and integrity of electrical and electronic systems worldwide. Whether in automotive, electronics, industrial, or telecommunications sectors, investing in quality slit corrugated sleeving is a proactive step toward preserving the functionality and longevity of critical wiring systems.