silent sync belt

Understanding Silent Sync Belts The Quiet Marvel of Mechanical Engineering

In the realm of mechanical engineering, the silent sync belt has emerged as a remarkable innovation, offering a plethora of advantages that address common challenges faced in various industrial applications. Known for their efficiency and noise reduction capabilities, silent sync belts have carved a niche for themselves in the world of power transmission systems. This article aims to explore the features, benefits, and applications of silent sync belts, shedding light on why they are quickly becoming a preferred choice in many industries.

What is a Silent Sync Belt?

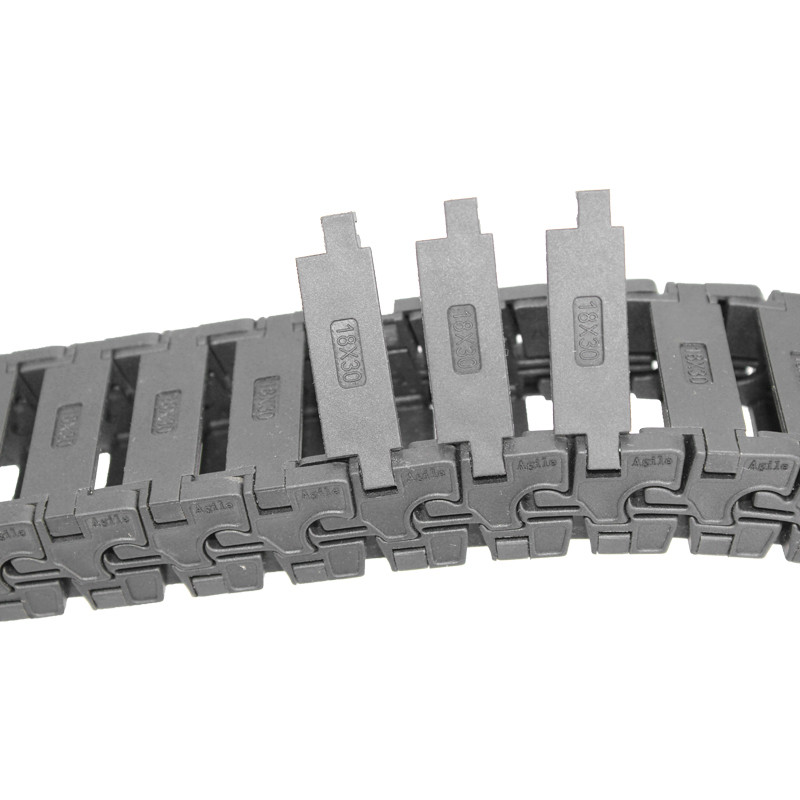

A silent sync belt, often referred to as a synchronous belt, is a type of belt that engages with teeth rather than relying on friction alone, as is common with traditional V-belts. This toothed design allows for precise movement and eliminates slippage, ensuring that the belt maintains a synchronous relationship with the pulleys it operates on. The “silent” aspect of these belts is derived from the minimized noise level during operation, largely due to their unique manufacturing process and material composition.

Features of Silent Sync Belts

Several features set silent sync belts apart from traditional belt systems

1. Toothed Design The teeth on the inner side of the belt engage with corresponding grooves on the pulleys. This design provides a firm grip, preventing slippage and ensuring accurate timing—an essential factor in applications where precision is crucial.

2. Reduced Noise Levels One of the most significant advantages of silent sync belts is their ability to operate with minimal noise. The design and materials used in these belts help dampen vibrations, making them ideal for environments where noise reduction is a priority, such as in office equipment, robotics, and other sensitive applications.

3. High Load Capacity Silent sync belts are engineered to handle high loads while maintaining efficiency. Their construction allows for effective power transmission, making them suitable for demanding applications across various industries.

4. Durability Made from high-quality materials, silent sync belts exhibit excellent resistance to wear, heat, and environmental factors. This durability translates to longer service life and lower maintenance requirements, making them a cost-effective choice in the long run.

Benefits of Using Silent Sync Belts

The adoption of silent sync belts in various industries comes with a multitude of benefits

silent sync belt

- Efficiency The precise engagement of teeth ensures that energy is effectively transmitted from motor to pulley, reducing energy losses that are common in traditional belt systems.

- Lower Operating Costs With reduced wear and lower maintenance requirements, silent sync belts contribute to significant cost savings over time.

- Versatility Silent sync belts can be utilized in a diverse array of applications, from light-duty machinery to heavy industrial equipment, showcasing their flexibility in meeting different operational demands.

- Improved Performance The ability to operate quietly and efficiently enhances the overall performance of machines and equipment, leading to better productivity and user satisfaction.

Applications of Silent Sync Belts

Silent sync belts find application in various sectors due to their remarkable properties. Some notable applications include

- Manufacturing Used in conveyor systems, automated assembly lines, and robotics, silent sync belts ensure smooth and precise movement of components.

- Automotive In vehicles, these belts can be found in engines and accessory drives where timing and noise reduction are critical.

- Consumer Electronics Many household appliances, such as printers and DVD players, utilize silent sync belts for their ability to operate quietly.

- HVAC Systems Silent sync belts are employed in heating, ventilation, and air conditioning systems, promoting efficient airflow with reduced noise levels.

Conclusion

Silent sync belts represent a significant advancement in the field of mechanical engineering, providing solutions that are not only efficient but also silent. Their unique features, combined with the numerous benefits they offer, have made them an indispensable component in a variety of industries. As technology continues to evolve, the demand for solutions that enhance performance while minimizing noise will likely lead to even greater innovations in belt systems and power transmission technologies. Whether in manufacturing, automotive, or consumer electronics, silent sync belts are indeed a quiet marvel that contributes to a smoother, more efficient operation.