Flexible Shaft Bellows Covers for Enhanced Protection and Durability in Machinery Applications

Shaft Bellows Covers An Essential Component for Machinery Protection

In the world of machinery and mechanical systems, the importance of protective components cannot be overstated. Among these, shaft bellows covers play a crucial role in safeguarding shafts and other mechanical elements from contaminants, moisture, and physical damage. This article explores the significance, types, applications, and benefits of using shaft bellows covers in various industrial settings.

What are Shaft Bellows Covers?

Shaft bellows covers are flexible, tube-like components that encase the shafts of machinery to protect them from external elements. Made from a variety of durable materials such as rubber, neoprene, or other synthetic compounds, these covers are designed to withstand harsh conditions while maintaining their flexibility. They can be found in different shapes and sizes, tailored to fit specific machinery applications.

Importance of Bellows Covers

The primary function of shaft bellows covers is to protect shafts from dirt, dust, debris, and moisture, all of which can lead to premature wear or failure. By keeping contaminants out, bellows covers help to ensure the longevity and efficient operation of machinery. Furthermore, they also provide a degree of thermal insulation, protecting sensitive components from extreme temperatures.

In environments where precision and cleanliness are vital, such as in the food and pharmaceutical industries, the use of shaft bellows covers becomes even more critical. They help maintain hygiene standards by creating a barrier that prevents the ingress of particles that could contaminate products.

Types of Shaft Bellows Covers

Shaft bellows covers can be classified into several types based on their design and application

1. Conical Bellows Covers These have a tapered design and are typically used for applications where space is limited. They provide a snug fit and excel at protecting against particulate ingress.

2. Cylindrical Bellows Covers Offering a more uniform shape, cylindrical bellows covers are commonly used in applications where a greater range of motion is required. They can extend and retract as the machinery operates.

3. Universal Bellows Covers These are premade covers designed to fit a range of shaft sizes and applications. While they offer flexibility, they may not provide the same level of protection as bespoke solutions.

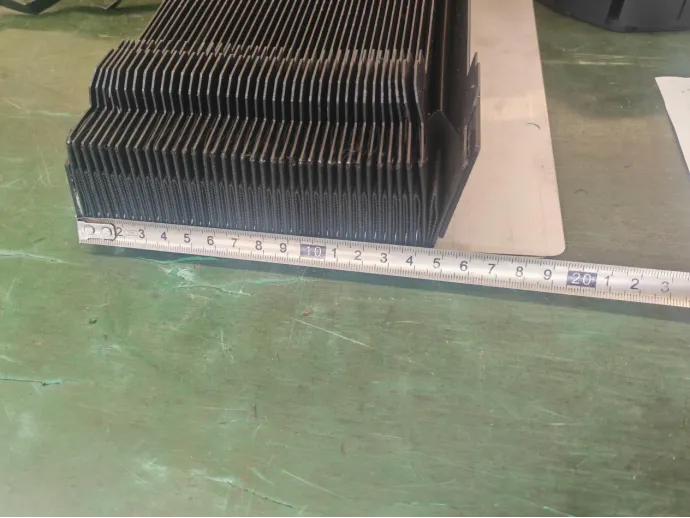

shaft bellows covers

Applications

Shaft bellows covers find their application across various industries, including

- Manufacturing In factories, machinery such as lathes, milling machines, and CNC equipment utilize bellows covers to protect critical components from chips and coolant. - Automotive In the automotive sector, bellows covers can be found on steering racks and suspension systems, providing protection against dirt and moisture to ensure reliability and longevity.

- Robotics With the increasing integration of robotics in manufacturing, bellows covers are essential for safeguarding moving parts against dust and debris.

- Food Processing In environments where hygiene is paramount, bellows covers help in maintaining the cleanliness of moving parts, aligning with stringent industry regulations.

Benefits of Using Shaft Bellows Covers

Installing shaft bellows covers offers numerous benefits

- Increased Longevity By protecting shafts from wear and tear, bellows covers significantly extend the lifespan of machinery. - Reduced Maintenance Costs With fewer maintenance requirements stemming from contamination and damage, companies can save on repair and replacement costs.

- Enhanced Performance Maintaining clean components ensures that machinery operates at peak efficiency, minimizing downtime.

- Versatility With various materials and designs available, shaft bellows covers can be tailored to suit a wide range of environments and applications.

Conclusion

Shaft bellows covers are more than just protective cases; they are essential components in maintaining the integrity and performance of machinery across various industries. Their ability to guard against contaminants, reduce maintenance costs, and prolong equipment life makes them an indispensable part of mechanical systems. As technology advances and industries evolve, the role of shaft bellows covers will continue to be pivotal in ensuring reliable and efficient operations. Whether in manufacturing, automotive, or food processing, investing in quality bellows covers is a decision that pays dividends in the long run.