Efficient Screw Conveyor Systems for Chip Management and Metal Processing Industries

The Importance of Screw Chip Conveyors in Modern Manufacturing

In the realm of modern manufacturing, efficient material handling systems are crucial to maintaining productivity and optimizing workflow. One such system that has gained prominence is the screw chip conveyor. These conveyors are designed specifically to transport metal chips and shavings produced during machining processes. Their efficiency, reliability, and versatility make them an essential component in various manufacturing settings.

Screw chip conveyors operate on a simple yet effective principle. They utilize a rotating helical screw blade, which effectively moves materials along a casing. This design allows for the continuous movement of chips and shavings, minimizing the risk of clogging and ensuring a clean working environment. The enclosed structure of the conveyor also protects sensitive machinery from debris, preventing potential damage and reducing maintenance costs.

A key advantage of screw chip conveyors is their ability to handle a diverse range of materials. Whether dealing with aluminum, steel, or plastic chips, these conveyors are built to withstand the rigors of metalworking operations. Their versatility makes them suitable for various applications, from CNC machining centers to lathes and milling machines.

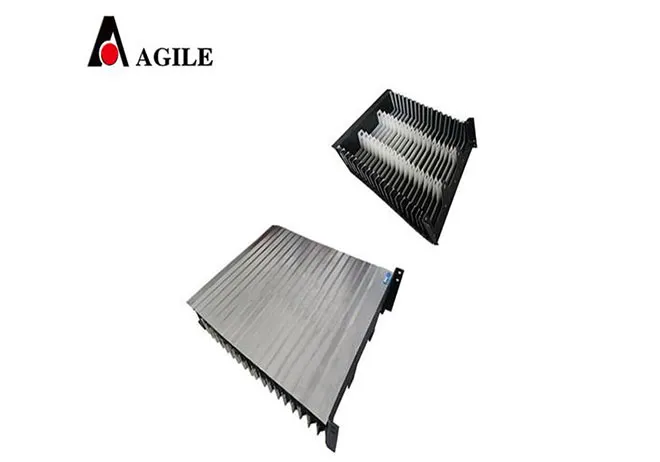

screw chip conveyor

Another significant benefit of screw chip conveyors is their space-saving design

. Unlike traditional conveyor systems, which may require extensive floor space, screw conveyors can be installed in tighter areas, making them ideal for facilities with limited room. They can be oriented in different angles, including horizontal and vertical configurations, further enhancing their adaptability to existing layouts.Efficiency is another hallmark of screw chip conveyors. By ensuring that chips are removed promptly from the machining process, manufacturers can significantly reduce the risk of tool wear and tear. This proactive approach to waste management leads to improved equipment longevity and higher production rates, ultimately contributing to a company’s bottom line.

Moreover, modern screw chip conveyors come with advanced features such as automated controls, which allow for seamless integration into existing manufacturing systems. These controls can optimize the flow of materials, monitor system performance, and even provide real-time data analysis. As innovation continues to shape the manufacturing landscape, screw chip conveyors are evolving to become smarter and more efficient.

In conclusion, screw chip conveyors play a vital role in the modern manufacturing environment. Their efficiency, space-saving design, and adaptability to various materials make them indispensable for effective waste management. As technology continues to advance, these conveyors will undoubtedly remain at the forefront of material handling solutions, driving productivity and ensuring cleaner, safer workplaces.