Screw Chip Conveyor Systems for Efficient Chip Management in Industrial Applications

The Importance of Screw Chip Conveyors in Modern Manufacturing

In the fast-paced world of manufacturing, efficiency and productivity are paramount. One essential component that aids in these efforts is the screw chip conveyor. This specialized equipment plays a crucial role in the management and transportation of metal chips and shavings generated during machining processes. As industries evolve and technologies advance, understanding the significance and functionality of screw chip conveyors becomes increasingly important.

What is a Screw Chip Conveyor?

A screw chip conveyor is a mechanical device designed to transport metal chips, scrap, and other by-products away from machining equipment. It consists of a helical screw blade, or auger, mounted inside a trough or housing, which rotates to move materials along its length. The design allows for the efficient collection and transfer of chips in a continuous flow, reducing the risk of equipment clogging and enhancing workshop safety.

Key Features and Benefits

One of the primary advantages of screw chip conveyors is their versatility. They can be used in various applications, including lathes, milling machines, and grinding equipment. Their compact design allows them to fit into tight spaces, making them ideal for modern manufacturing environments where space optimization is critical.

Moreover, screw chip conveyors are designed to handle various types of materials, including aluminum, steel, and plastic chips

. The ability to transport different materials ensures that manufacturers can adapt to changing production requirements without the need for significant equipment overhauls.Another notable feature is the durability and robustness of screw chip conveyors. Constructed from high-quality materials, these conveyors are engineered to withstand the rigors of continuous operation, which minimizes downtime and maintenance costs. The components are often designed with wear resistance in mind, ensuring a longer service life even when dealing with abrasive metal chips.

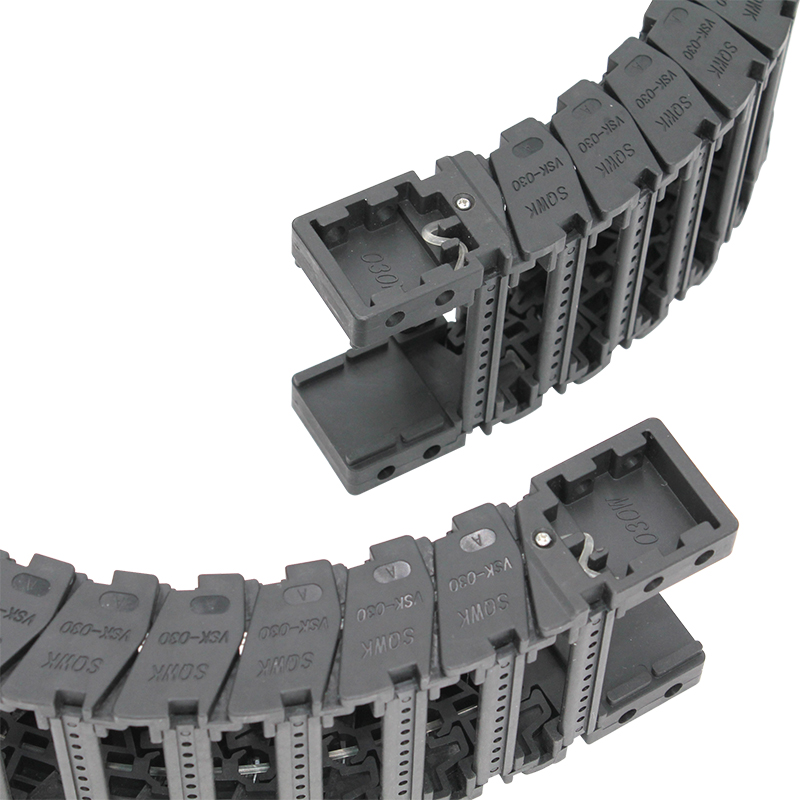

screw chip conveyor

Efficiency and Productivity

In a typical manufacturing setting, the accumulation of metal chips can hinder production processes. Chips not only occupy valuable workspace but can also pose safety hazards if left unmanaged. Screw chip conveyors efficiently remove these by-products, significantly improving workflow and productivity. By maintaining a clean and organized work environment, manufacturers can enhance safety and reduce the risk of accidents caused by cluttered workspaces.

Additionally, by implementing a screw chip conveyor system, companies can facilitate recycling efforts. Instead of discarding metal shavings as waste, these conveyors can transport them to recycling systems where the material can be repurposed. This not only contributes to sustainability initiatives but also presents potential cost savings for manufacturers who can reclaim valuable materials.

Care and Maintenance

To maximize the effectiveness of screw chip conveyors, regular maintenance is essential. Manufacturers should establish a routine inspection schedule to check for wear and tear, ensure that components are properly lubricated, and verify that the conveyor is functioning smoothly. This proactive approach helps prevent unexpected breakdowns and extends the lifespan of the equipment.

Moreover, operators should be trained to recognize early signs of potential issues, such as unusual noises or decreased performance. By addressing these concerns promptly, manufacturers can avoid costly repairs and maintain seamless production.

Conclusion

Screw chip conveyors are invaluable assets in today's manufacturing landscape. By providing efficient chip removal, promoting workplace safety, and supporting recycling efforts, they play a vital role in enhancing productivity and operational efficiency. As technology continues to advance, the design and functionality of screw chip conveyors are likely to evolve, further solidifying their position as essential equipment in modern manufacturing processes. For businesses looking to streamline operations and improve their production capabilities, investing in a reliable screw chip conveyor system is a strategic move that can yield significant returns.