rubber bellows dust boot

The Importance of Rubber Bellows and Dust Boots A Comprehensive Overview

Rubber bellows and dust boots play a crucial role in various industries by providing essential protection to mechanical components. These flexible structures are designed to accommodate movement, prevent contamination, and ensure the longevity of equipment. Understanding the significance of these components can help businesses optimize their operations and reduce maintenance costs.

What Are Rubber Bellows and Dust Boots?

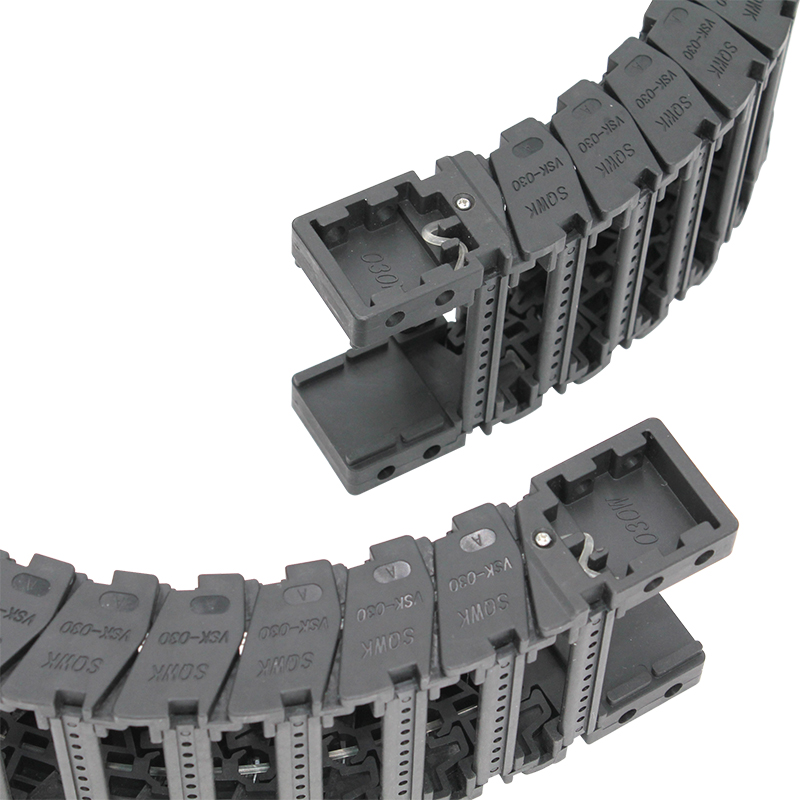

Rubber bellows are flexible, cylindrical components made of elastomeric materials, commonly rubber or silicone. They can expand and contract, making them ideal for applications where movement is expected. Dust boots, on the other hand, are protective coverings designed to shield sensitive parts from dirt, dust, and other environmental contaminants. Often used in conjunction with bellows, dust boots play an equally vital role in prolonging the service life of machinery.

Applications in Various Industries

One of the primary applications of rubber bellows is in the automotive industry. They are commonly used to protect joints, such as drive shafts and steering systems, from dirt and moisture, which can lead to premature wear and tear. By sealing these components, rubber bellows ensure that lubrication remains intact, thereby enhancing performance and ensuring safety.

In the manufacturing sector, rubber bellows and dust boots are utilized in machinery such as CNC equipment and robotic arms. These parts protect moving components from contaminants that could jeopardize precision and operational efficiency. The wear and damage of machinery can lead to costly downtime, making the protection provided by bellows and dust boots indispensable.

rubber bellows dust boot

Furthermore, in the aerospace and marine industries, rubber bellows help in accommodating movement due to expansion and contraction in extreme temperatures. They are crucial for sealing and protecting various systems, including hydraulic and pneumatic systems, against the ingress of debris and moisture. This protection is paramount, given the high-stakes environments in which these systems operate.

Durability and Material Considerations

When selecting rubber bellows and dust boots, durability and material composition are critical factors. The choice of material often depends on the specific application and environmental conditions to which they will be exposed. For example, silicone rubber is preferred in high-temperature applications due to its stability, while neoprene is often chosen for its resistance to oils and chemicals.

In addition to material selection, the design of bellows and dust boots can vary widely, with options including convoluted (pleated) designs that provide greater flexibility and expansion capabilities. Custom-designed bellows can be manufactured to meet specific dimensions and operational requirements, ensuring optimal performance in various applications.

Conclusion

In conclusion, rubber bellows and dust boots are essential components that provide protection and enhance the functionality of various mechanical systems. Their adaptability and resilience make them invaluable in numerous industries, including automotive, manufacturing, aerospace, and marine sectors. By understanding the role and importance of these components, businesses can make informed decisions about their utilization, leading to improved operational efficiency and reduced maintenance costs. Investing in high-quality rubber bellows and dust boots is not just a purchase but a strategic move towards ensuring equipment longevity and reliability.