rubber bellow cover

Understanding Rubber Bellow Covers Purpose, Design, and Applications

Rubber bellow covers are essential components in various mechanical and engineering applications. They serve a critical function in protecting moving parts and enhancing the lifespan of machinery. This article explores the design, purpose, and applications of rubber bellow covers, highlighting their importance in industrial settings.

What Are Rubber Bellow Covers?

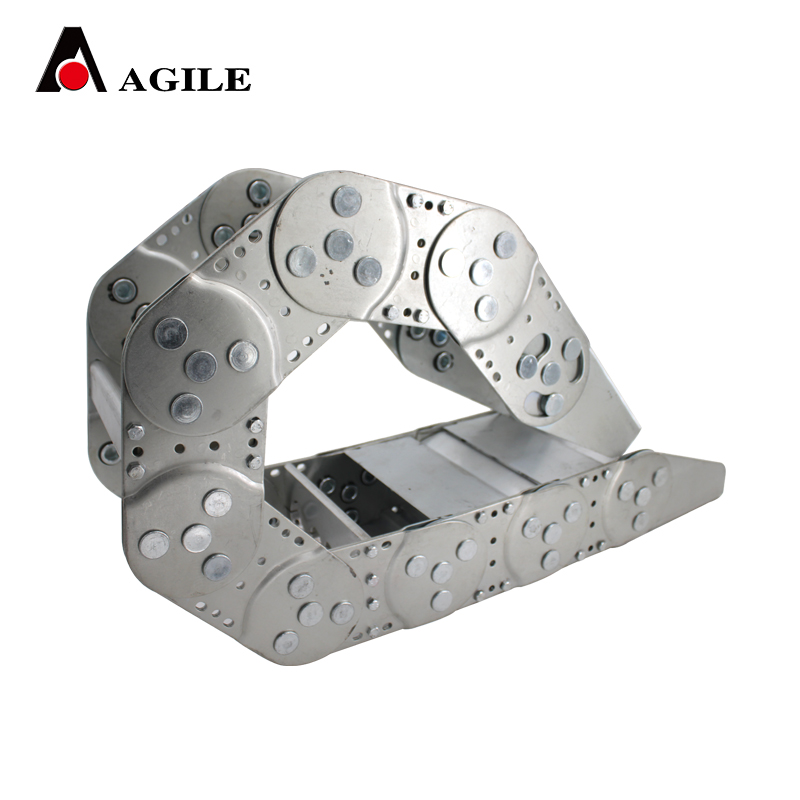

Rubber bellow covers, often referred to as bellows or bellows covers, are flexible, expandable covers made from rubber or other elastomeric materials. Their primary design is to provide protection for mechanical components from environmental factors such as dust, dirt, moisture, and other contaminants.

These covers are typically designed to expand and contract with the movement of the parts they protect, allowing for adequate motion while maintaining a seal against harmful elements. This flexibility is crucial in applications where components undergo constant motion, such as in linear actuators, machine tools, and automotive systems.

Design Features

The design of rubber bellow covers includes various features that enhance their functionality and adaptability to specific applications. The material used in manufacturing bellows is typically formulated to withstand wear and tear, temperature fluctuations, and chemical exposure. It may include synthetic rubbers like neoprene, nitrile, or silicone, each chosen for their unique properties.

Rubber bellow covers come in various shapes and sizes, depending on their specific application requirements. They can be cylindrical, conical, or custom-shaped to fit particular machine compartments. The thickness of the rubber can also vary to provide the necessary durability and flexibility.

The sealing mechanism is another essential aspect of their design. Many rubber bellow covers are equipped with metal rings or frames to enhance stability and provide a secure fit. These features ensure that the bellow remains attached to the machinery, providing effective protection throughout its operational life.

Purpose of Rubber Bellow Covers

rubber bellow cover

The primary purpose of rubber bellow covers is protection. By shielding moving parts from external contaminants, they help extend the life of machinery, reducing the risk of breakdowns and maintenance costs. Here are some specific functions they serve

1. Dust and Dirt Protection In environments where dust and dirt are prevalent, rubber bellow covers prevent particles from entering critical components, such as guide rails, screws, and mechanisms. This is crucial for maintaining smooth operation and enhancing longevity.

2. Moisture Resistance Many machines operate in environments where moisture exposure is inevitable. Rubber bellows are designed to resist water and prevent corrosion and rust on vulnerable components.

3. Containment of Lubricants In machines that require lubrication, rubber bellow covers help contain oils and greases, preventing them from spilling out and ensuring that mechanical parts remain properly lubricated.

4. Safety Enhancement By enclosing moving parts, rubber bellow covers can help prevent accidents by keeping operators safe from protruding machinery parts.

Applications of Rubber Bellow Covers

Rubber bellow covers are utilized across various industries, including manufacturing, automotive, aerospace, and robotics. Their versatility makes them ideal for a wide range of applications

- Machine Tools In CNC machines and lathes, rubber bellow covers protect sensitive components from debris and machining fluids. - Automotive Systems In cars, bellows are used to protect steering mechanisms and drive shaft joints, ensuring smooth operation and extending service life. - Industrial Equipment In conveyor systems and packaging machinery, rubber bellows safeguard electrical components and moving parts from dust and moisture. - Robotics In robotic applications, these covers ensure that servo motors and actuators remain free from any contaminant that could interfere with their precise movements.

Conclusion

Rubber bellow covers play a pivotal role in safeguarding machinery and equipment across various industries. Their flexible design, combined with robust materials, makes them indispensable for protecting critical components from environmental factors. Understanding their purpose and applications highlights the importance of investing in quality rubber bellow covers to enhance operational efficiency and equipment longevity. As industries continue to evolve, the demand for effective protective measures like rubber bellow covers will undoubtedly grow, underscoring their significance in modern technology.