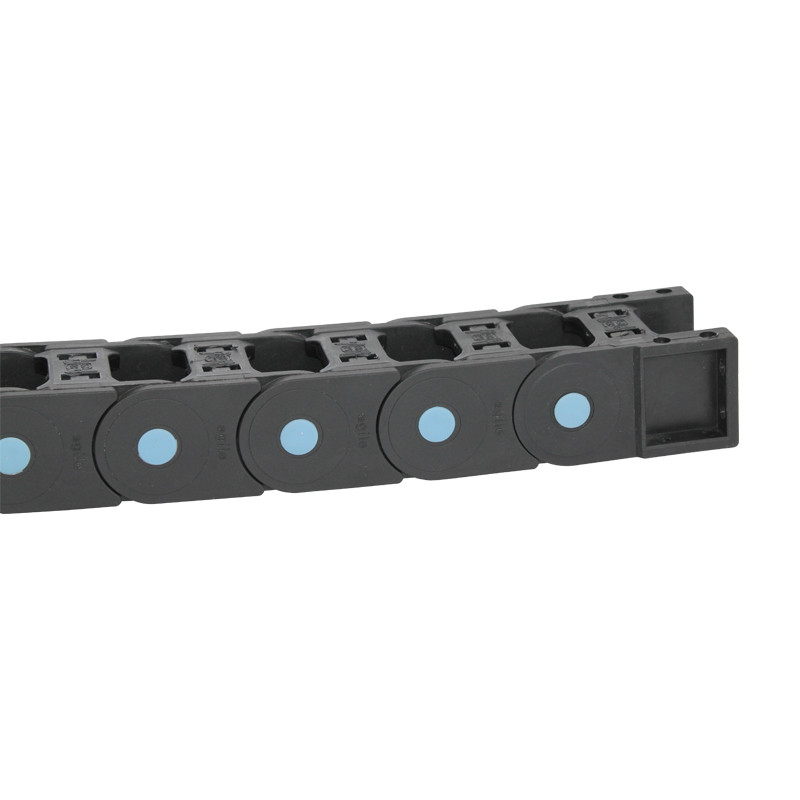

robodrill chip conveyor

The RoboDrill Chip Conveyor Revolutionizing Machining Efficiency

In the ever-evolving world of manufacturing and machining, efficiency and productivity are paramount. One of the crucial innovations in this sector is the RoboDrill chip conveyor, a sophisticated system designed to streamline the machining process by effectively managing the by-products of machining operations—metal chips and swarf.

The RoboDrill Chip Conveyor Revolutionizing Machining Efficiency

One of the key advantages of the RoboDrill chip conveyor is its ability to handle various types of metal chips, whether they are long and stringy or small and granular. This adaptability ensures that no matter the project or the machining parameters used, the conveyor can effectively manage the waste produced, minimizing manual labor and maintenance needs. By automating the chip removal process, the conveyor also reduces the risk of machine damage due to chip accumulation, prolonging the lifespan of the machining equipment.

robodrill chip conveyor

Moreover, the RoboDrill chip conveyor is designed for easy integration and flexibility. It can be customized to fit different workshop layouts and can work in conjunction with other automated systems. This modularity allows manufacturers to adapt their machinery to meet the changing demands of production without needing extensive renovations or costly upgrades. Additionally, its energy-efficient design supports sustainability efforts within manufacturing processes, contributing to reduced operational costs in the long run.

In terms of maintenance, the RoboDrill chip conveyor is engineered for reliability and long-term use. Its robust construction ensures minimal wear and tear, while easy access for cleaning and servicing means that companies can ensure their systems operate at peak performance without excessive downtime.

The benefits of the RoboDrill chip conveyor extend beyond mere efficiency; it plays a significant role in enhancing workplace safety. With automatic chip removal, the risk of slips and falls decreases, creating a safer environment for workers. Furthermore, a clean workspace promotes better focus and productivity, ultimately leading to higher quality outputs.

In conclusion, the RoboDrill chip conveyor represents a significant advancement in the field of machining, addressing the critical challenges of chip management and workplace efficiency. With its ability to streamline operations, enhance safety, and reduce maintenance needs, it is an invaluable asset for modern manufacturing environments. As industries continue to adapt to advances in technology, systems like the RoboDrill chip conveyor will undoubtedly lead the way toward smarter, more efficient machining solutions.