Exploring the Benefits of RoboDrill Chip Conveyors for Enhanced Efficiency and Productivity

The Importance of Chip Conveyors in RoboDrill Systems

In the realm of advanced machining, the RoboDrill stands out as a beacon of efficiency and precision. However, the capabilities of this machine are not solely determined by its design and engineering; rather, they are significantly enhanced by the integration of chip conveyors. Chip conveyors play a crucial role in maintaining the operational integrity and productivity of RoboDrill systems, ensuring that the machining process is smooth and uninterrupted.

Enhancing Machining Efficiency

One of the most significant advantages of incorporating a chip conveyor into a RoboDrill setup is the enhancement of machining efficiency. As metal is machined, chips and shavings are generated, which can accumulate quickly if not managed properly. A chip conveyor efficiently removes these chips from the machining area, preventing them from interfering with the cutting process. By minimizing the buildup of debris, the conveyor system ensures that the cutting tools maintain optimal contact with the workpiece, enabling the RoboDrill to perform at its best.

Moreover, an effective chip management system reduces downtime significantly. Without a conveyor, operators might need to stop machining frequently to clear chips manually, which interrupts workflow and affects productivity. With a reliable chip conveyor in place, RoboDrill can maintain continuous operation, greatly increasing output and improving overall efficiency.

Types of Chip Conveyors

Chip conveyors come in various designs, each tailored to meet specific requirements based on the type of material being machined and the nature of the operation. Some common types include

1. Scraper Conveyors These utilize a series of scrapers or blades to push the chips along a track. They are particularly effective for larger chips and metal shavings, ensuring they are efficiently removed from the machining area.

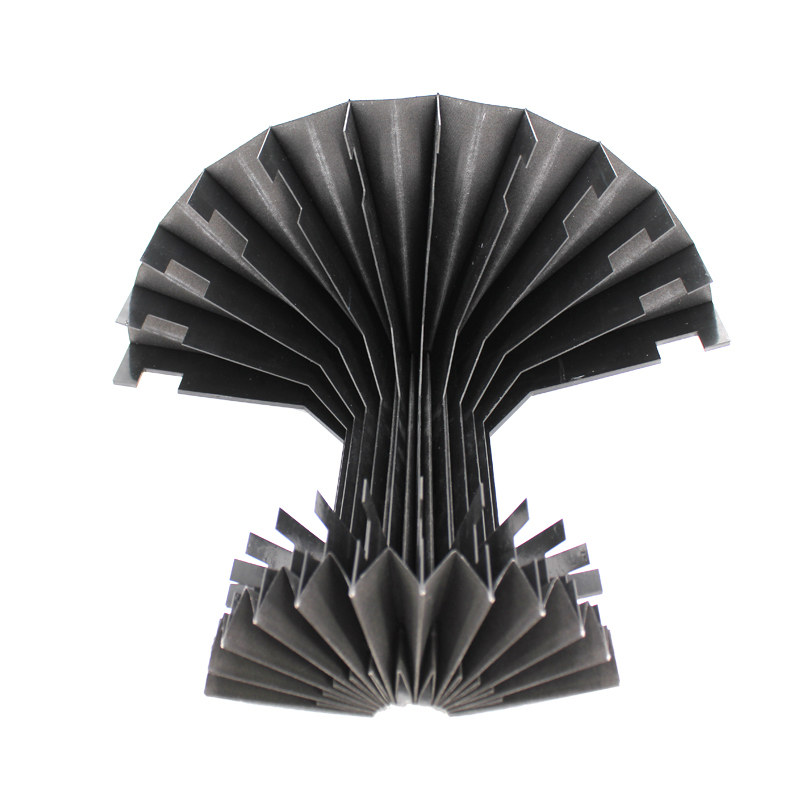

robodrill chip conveyor

2. Magnetic Conveyors For ferrous materials, magnetic conveyors are an excellent choice. They use magnetic forces to lift and transport metal chips, preventing them from falling back into the workspace.

3. Auger Conveyors These employ a rotating screw mechanism to move chips. They are versatile and can handle an array of materials, making them suitable for mixed environments.

Choosing the right type of conveyor is critical for optimizing the performance of the RoboDrill, as it directly affects how efficiently chips are handled during machining processes.

Importance of Maintenance and Care

The proper functioning of chip conveyors is vital for the overall performance of the RoboDrill. Regular maintenance is necessary to ensure that the conveyors operate smoothly and effectively. Operators must rotate the conveyor belts, check for blockages, and maintain cleanliness to prevent malfunctions. Neglecting this maintenance can lead to the conveyor becoming clogged, resulting in system failures that can halt production.

Additionally, integrating sensor technology can further enhance the efficiency of chip conveyors. Sensors can monitor the level of chips in the conveyor and automate the process of chip removal, ensuring that the RoboDrill never experiences interruptions due to chip buildup.

Conclusion

In summary, chip conveyors are an indispensable component of RoboDrill systems that enhance machining efficiency and productivity. By managing the removal of chips during operation, they ensure that the cutting tools work effectively without interruption. Given the variety of chip conveyor types available, selecting the right system tailored to specific machining needs is crucial. Regular maintenance and the use of technology can further optimize these systems, providing operators with the reliability and efficiency necessary in today’s competitive manufacturing landscape. As industries continue to embrace automation and advanced machining techniques, the importance of chip conveyors will only grow, paving the way for ever more efficient machining solutions within RoboDrill systems.