protective wire loom

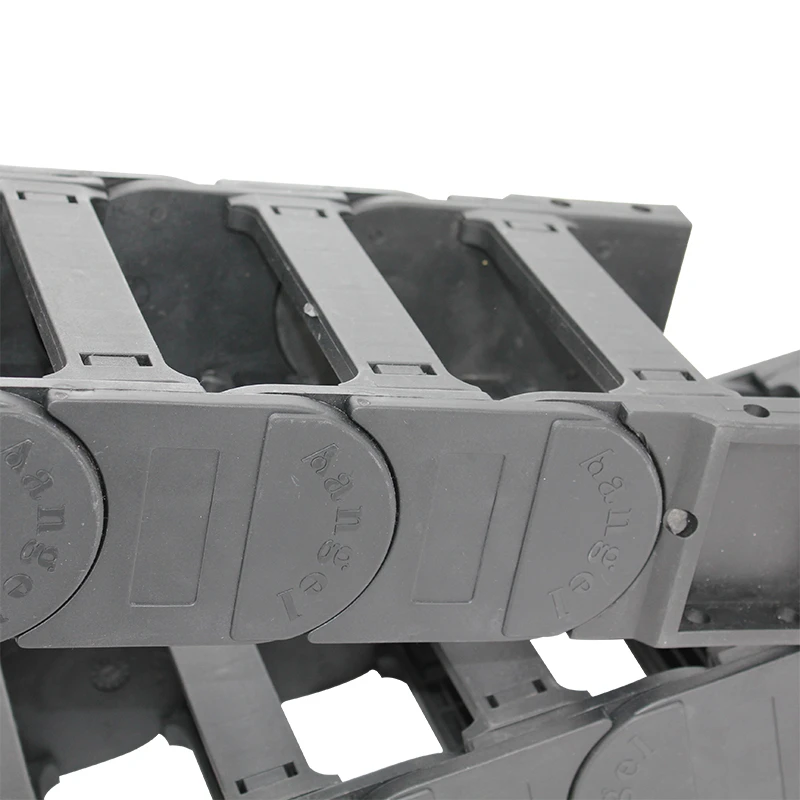

The world of cable management can often feel complex and overwhelming, especially for those unfamiliar with the nuances of protective systems. However, the use of protective wire loom proves instrumental in ensuring the durability and performance of electrical systems across various industries. Throughout my extensive experience as an expert in cable management solutions, I have come to appreciate the unparalleled benefits of wire loom.

In my capacity as a professional dealing with numerous protective wire loom applications, I emphasize the importance of assessing environmental conditions and specific application requirements before choosing a loom type. It’s essential to consider factors such as the operating temperature range, potential chemical exposure, and any physical stress the wiring may endure. Leveraging such expertise enables a tailored approach, ensuring the protective wire loom selected optimally serves its purpose. Trustworthiness is a cornerstone of implementing protective wire loom solutions. The assurance that systems will operate without unexpected failures builds trust between service providers and their clients. As specialists in cable management, we guarantee the reliability of our recommendations based on empirical evidence and industry best practices. Our methodologies evolve with technological advancements, ensuring the solutions we advocate remain cutting-edge. Authoritativeness in the realm of protective wire loom stems from continual research and development. Manufacturers committed to innovation provide products that consistently meet industry standards and certifications, further reinforcing their authority in this field. Trust is engendered through transparent communication of these standards, offering users peace of mind that their wire loom solutions are second to none. Ultimately, the integration of protective wire loom into cable management schemes is an invaluable asset that cannot be overstated. Product knowledge, coupled with real-life application experience, fortifies the foundations upon which current and future infrastructure relies. Leveraging authoritative resources and proven expertise, businesses and individual consumers alike can rest assured that their wiring systems are optimally protected against the challenges they face. As I continue to advocate for such practical solutions, I am reminded of the significant role protective wire loom plays in enhancing the reliability and efficiency of complex electrical systems.

In my capacity as a professional dealing with numerous protective wire loom applications, I emphasize the importance of assessing environmental conditions and specific application requirements before choosing a loom type. It’s essential to consider factors such as the operating temperature range, potential chemical exposure, and any physical stress the wiring may endure. Leveraging such expertise enables a tailored approach, ensuring the protective wire loom selected optimally serves its purpose. Trustworthiness is a cornerstone of implementing protective wire loom solutions. The assurance that systems will operate without unexpected failures builds trust between service providers and their clients. As specialists in cable management, we guarantee the reliability of our recommendations based on empirical evidence and industry best practices. Our methodologies evolve with technological advancements, ensuring the solutions we advocate remain cutting-edge. Authoritativeness in the realm of protective wire loom stems from continual research and development. Manufacturers committed to innovation provide products that consistently meet industry standards and certifications, further reinforcing their authority in this field. Trust is engendered through transparent communication of these standards, offering users peace of mind that their wire loom solutions are second to none. Ultimately, the integration of protective wire loom into cable management schemes is an invaluable asset that cannot be overstated. Product knowledge, coupled with real-life application experience, fortifies the foundations upon which current and future infrastructure relies. Leveraging authoritative resources and proven expertise, businesses and individual consumers alike can rest assured that their wiring systems are optimally protected against the challenges they face. As I continue to advocate for such practical solutions, I am reminded of the significant role protective wire loom plays in enhancing the reliability and efficiency of complex electrical systems.