Durable Protective Bellows Covers for Enhanced Equipment Safety and Longevity

The Importance of Protective Bellows Covers in Industrial Applications

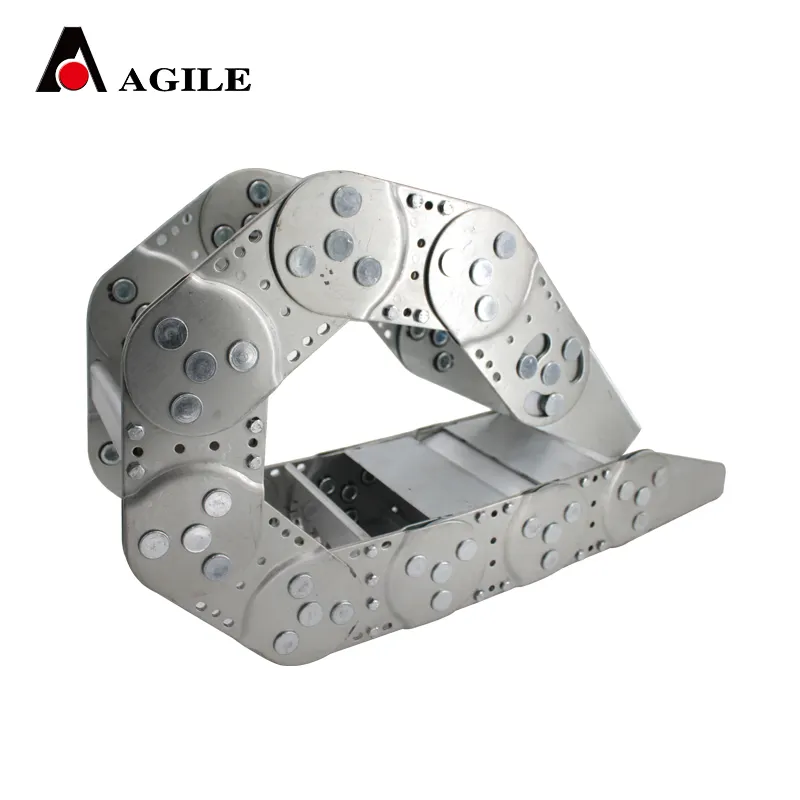

In various industrial sectors, equipment and machinery often face harsh environments that can lead to wear and tear over time. One of the most effective solutions to mitigate this damage is the use of protective bellows covers. These versatile components play a crucial role in safeguarding mechanical systems from debris, moisture, and other potentially damaging elements. Understanding their functionality and benefits can help industries maintain the longevity and efficiency of their equipment.

What Are Protective Bellows Covers?

Protective bellows covers are flexible, expandable enclosures typically made from materials like rubber, PVC, or polyurethane. They are designed to shield moving parts, particularly those in machinery, from dirt, dust, chemicals, and moisture. The bellows can be custom-fabricated to fit a variety of shapes and sizes, making them suitable for an extensive range of applications.

Bellows covers are often used around telescoping components, guideways, and linear actuators. By providing a protective barrier, they prevent contaminants from entering critical areas such as bearings, gears, and motors, which can lead to premature failure and costly repairs.

Benefits of Using Protective Bellows Covers

1. Protection Against Contamination One of the primary functions of bellows covers is to keep contaminants at bay. In environments like manufacturing plants, sawmills, or construction sites, dust and debris can accumulate rapidly. Protective bellows ensure that moving parts remain clean, thus minimizing the risk of operational disruptions.

2. Moisture Resistance Many industrial applications involve exposure to water or other liquids. Protective bellows covers provide a barrier against moisture, which helps prevent rust and corrosion on sensitive components. This moisture resistance is crucial for maintaining the performance and reliability of machinery over time.

protective bellows covers

3. Enhanced Durability The materials used to manufacture bellows covers are selected for their durability and resistance to wear and tear. This resilience means that bellows can withstand harsh environmental conditions, including extreme temperatures and chemical exposure, ensuring long-lasting protection for the equipment beneath.

4. Cost-Effective Maintenance Implementing protective bellows covers can significantly reduce maintenance costs over time. By preventing damage caused by contamination and moisture, industries can avoid the high expenses associated with repairs or replacements of damaged machinery. This leads to improved operational efficiency and lower overall costs.

5. Customizability Protective bellows covers can be tailored to fit specific equipment requirements. They can be designed in various shapes, sizes, and configurations to accommodate different applications, making them a versatile solution for diverse industries.

Applications in Industry

The use of protective bellows covers spans multiple industries, including manufacturing, robotics, aerospace, automotive, and more. In CNC machines, for example, bellows covers are essential for protecting guideways and other moving parts from metal shavings and coolant. In robotics, they help shield delicate components from environmental hazards, ensuring consistent performance.

In the automotive industry, bellows covers are used to protect steering columns and other critical systems from contaminants. Aerospace applications similarly benefit, where the need for precision and reliability is paramount in the operation of aircraft and spacecraft.

Conclusion

Protective bellows covers are an integral part of modern industrial practices, providing essential protection to a wide range of components. Their ability to shield against dust, moisture, and environmental hazards not only extends the lifespan of machinery but also contributes to a more efficient and cost-effective operation. As industries continue to evolve, the demand for reliable protective solutions like bellows covers is sure to grow, highlighting their importance in maintaining the integrity of industrial equipment.