Protective Wire Loom - Durable and Flexible Wire Management Solutions

Understanding the Importance of Protective Wire Loom

In today's technologically advanced world, the need for effective wire management systems has never been more crucial. One such essential component is the protective wire loom. Designed to safeguard electrical wires and cables, wire looms play a vital role in various industries, including automotive, aerospace, and manufacturing.

What is Protective Wire Loom?

A protective wire loom is a tubular cover made from materials such as plastic, rubber, or nylon, designed to encase and protect electrical wires

. These looms prevent abrasion, damage from chemicals, and exposure to the elements, significantly extending the life of wiring harnesses in both residential and industrial settings.Benefits of Using Protective Wire Loom

1. Protection Against Physical Damage Wire looms shield cables from impacts and cuts, which can occur in environments with heavy machinery or sharp edges. This is particularly important in automotive applications where components are often subjected to vibrations and friction.

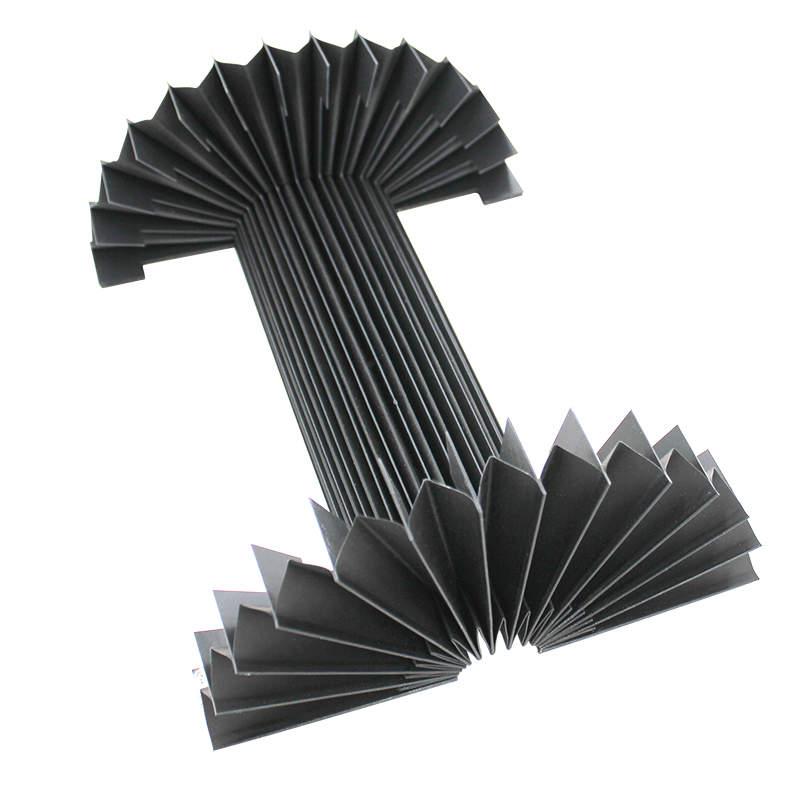

protective wire loom

2. Resistance to Environmental Factors Many protective wire looms are designed to withstand harsh environmental conditions, including extreme temperatures, UV exposure, and moisture. This resilience is crucial for outdoor installations, electronic devices, and vehicles that operate in diverse climates.

3. Organized Cable Management Using wire looms not only helps in protecting the wires but also promotes better organization. A tidy, well-managed wiring system reduces the risk of tangling and makes maintenance and troubleshooting easier.

4. Improved Aesthetics In settings where exposed wiring could detract from the appearance, wire looms provide a clean and professional look. This is especially relevant in consumer electronics and appliance design, where visual appeal may influence consumer choice.

5. Ease of Installation Many protective wire looms are designed for straightforward installation, often requiring minimal tools and time. This efficiency is a considerable advantage for manufacturers and technicians who aim to streamline production and repair processes.

Conclusion

In summary, protective wire looms are an indispensable aspect of modern wire management systems. Their ability to protect cables from physical damage, harsh environmental conditions, and organize complex wiring layouts significantly enhances the reliability and longevity of electrical systems. As industries continue to innovate and evolve, the demand for high-quality protective solutions like wire looms will only grow, affirming their crucial role in ensuring the safety and efficiency of electrical installations across various applications. Whether in the automotive sector, industrial automation, or home electronics, investing in protective wire looms is a step toward enhanced performance and durability in wiring systems.