poly split loom

The Journey of Poly Split Loom A Versatile Solution

In the realm of industrial manufacturing and DIY projects, the importance of protective and organizational materials cannot be overstated. Among these, the poly split loom has risen to prominence as a versatile solution for cable management and equipment protection. With its unique design and multifaceted applications, poly split loom is a key component in various sectors, including automotive, aerospace, and electrical engineering.

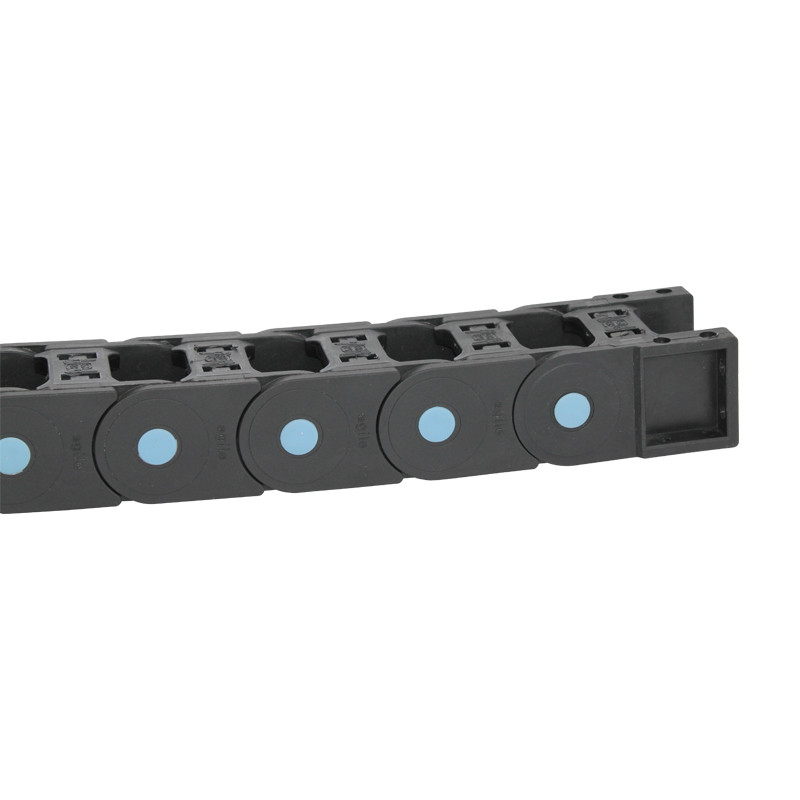

Poly split loom is crafted from durable polyethylene, a material known for its strength and resilience. The primary feature of split loom tubing is its split alongside its length, allowing for easy insertion of multiple wires or cables. This split design not only accommodates various sizes of cables but also provides flexibility, enabling users to adjust the arrangement as needed. Whether you are managing a complex array of wires in a control panel or routing cables in your home theater system, poly split loom offers a practical and efficient way to keep everything organized.

One of the most significant advantages of poly split loom is its protective properties. Electrical wires and cables are often susceptible to abrasion, chemical exposure, and environmental factors. Poly split loom acts as a shield, safeguarding delicate wiring from potential damage. This protection is particularly vital in industrial settings where equipment operates in harsh conditions or where cables are subjected to wear and tear. By using poly split loom, users can extend the lifespan of their cables and reduce the risk of electrical failures due to frayed wires.

poly split loom

Moreover, poly split loom contributes to the aesthetic organization of wiring systems. In installations where visual appeal is paramount—such as custom car wiring or home automation systems—neatly bundled cables encased in split loom tubing can dramatically enhance the overall appearance. The streamlined look not only prevents clutter but also simplifies troubleshooting and maintenance. Technicians can quickly identify specific cables when adjustments or replacements are necessary, thus saving valuable time and effort.

Environmental considerations also play a role in the popularity of poly split loom. As the demand for sustainable materials increases, manufacturers have begun producing poly split loom from recycled polyethylene. This innovation not only reduces waste but also promotes a more sustainable approach to cable management. By choosing eco-friendly split loom options, consumers can contribute to environmental conservation while enjoying the benefits of this versatile product.

The installation of poly split loom is straightforward, making it accessible even for DIY enthusiasts. Users can easily measure, cut, and secure the loom around their cables without the need for specialized tools or training. Many commercial suppliers offer a range of sizes and colors, allowing customers to select the most suitable option for their specific projects.

In conclusion, poly split loom has established itself as an indispensable tool for anyone involved in cable management. Its strength, flexibility, and protective qualities make it an excellent choice for a wide array of applications. As technology advances and environmental considerations come to the forefront, the role of poly split loom will undoubtedly continue to evolve, offering innovative solutions for both industrial and consumer needs. Whether you are an electrician, a DIY enthusiast, or simply someone looking to organize their home, poly split loom provides a practical, efficient, and aesthetically pleasing solution.