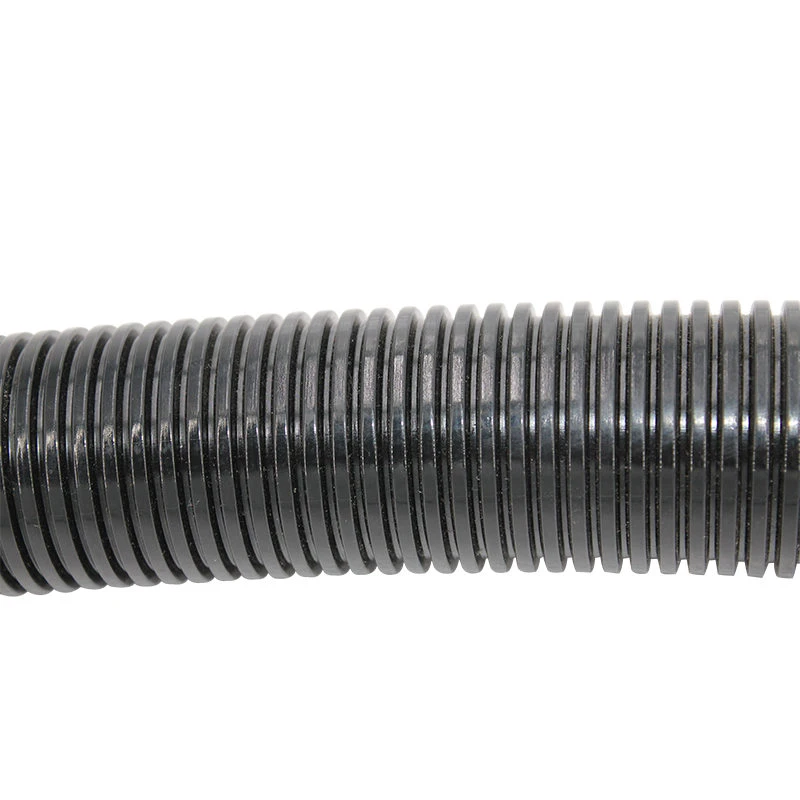

plastic split loom

Understanding Plastic Split Loom An Essential Tool for Cable Management

In our modern world, the proliferation of technology has resulted in an abundance of cables and wires. From household electronics to office devices, the presence of cables is often unavoidable. However, managing these cables efficiently is crucial to maintaining an organized and aesthetically pleasing environment. One of the most effective solutions for this challenge is the use of plastic split loom.

Plastic split loom is a flexible, tubular conduit that is primarily used to protect and organize wires and cables. Made from high-quality polyethylene, it provides a durable and lightweight option for safeguarding electrical wiring from abrasion, moisture, and other potential hazards. The split design allows for easy access and insertion of cables, making it a convenient choice for both DIY enthusiasts and professionals in various fields, including automotive, marine, and industrial applications.

Benefits of Using Plastic Split Loom

1. Cable Protection One of the primary benefits of plastic split loom is its ability to protect cables from physical damage. Wires, especially in mobile applications such as vehicles or machinery, are susceptible to wear and tear. The split loom acts as a barrier, reducing the risk of cuts and abrasions that can lead to shorts or electrical failures.

2. Organization A cluttered workspace can be distracting and hazardous. Plastic split loom helps in organizing multiple cables into a single, manageable unit. This not only enhances the visual appeal of an area but also makes it easier to identify and access specific cables when needed.

3. Flexibility and Versatility Plastic split loom is available in various sizes and lengths, making it suitable for a wide range of applications. Whether you are dealing with a few small wires or a bundle of larger cables, there is a split loom size that fits your needs. Its flexibility allows it to bend easily, accommodating tight spaces and corners without damaging the cables inside.

plastic split loom

4. Weather Resistance For applications exposed to outdoor elements, choosing a weather-resistant variant of plastic split loom is essential. High-density polyethylene (HDPE) variants offer excellent resistance to UV light, moisture, and extreme temperatures, ensuring long-lasting protection for outdoor wiring.

Installation and Maintenance

Installing plastic split loom is a straightforward process. Simply measure the length of the cables you wish to cover, cut the split loom to size, and insert the cables into the loom. If additional fastening is required, there are various accessories available, such as zip ties or clips, to secure the loom in place.

Maintenance of plastic split loom is minimal. Regular inspections can help identify any wear or damage, allowing for timely replacements. Staying proactive ensures that your cables remain protected and organized over time.

Conclusion

In conclusion, plastic split loom is an indispensable tool for anyone looking to manage cables effectively. Its benefits, ranging from protection against physical damage to enhancing organization, make it a preferred choice for a variety of industries. Whether you are a homeowner tackling a DIY project or a professional working in a challenging environment, implementing plastic split loom can significantly improve the way you manage your wiring systems. In an age where technology continues to evolve, having a reliable solution for cable management is more important than ever. Consider incorporating plastic split loom into your cable management strategy to enjoy the advantages of protection, organization, and ease of use it has to offer.