plastic split loom

Understanding Plastic Split Loom A Versatile Cable Management Solution

In today's technologically advanced world, the proliferation of cables and wires is a common sight in both residential and commercial settings. From home theaters to office setups, managing these cables effectively is crucial for aesthetics, safety, and functionality. One popular solution for cable organization is the plastic split loom, a flexible and durable tubing designed to protect and manage wires. This article explores the features, benefits, and applications of plastic split loom, demonstrating why it is an essential tool for any cable management project.

What is Plastic Split Loom?

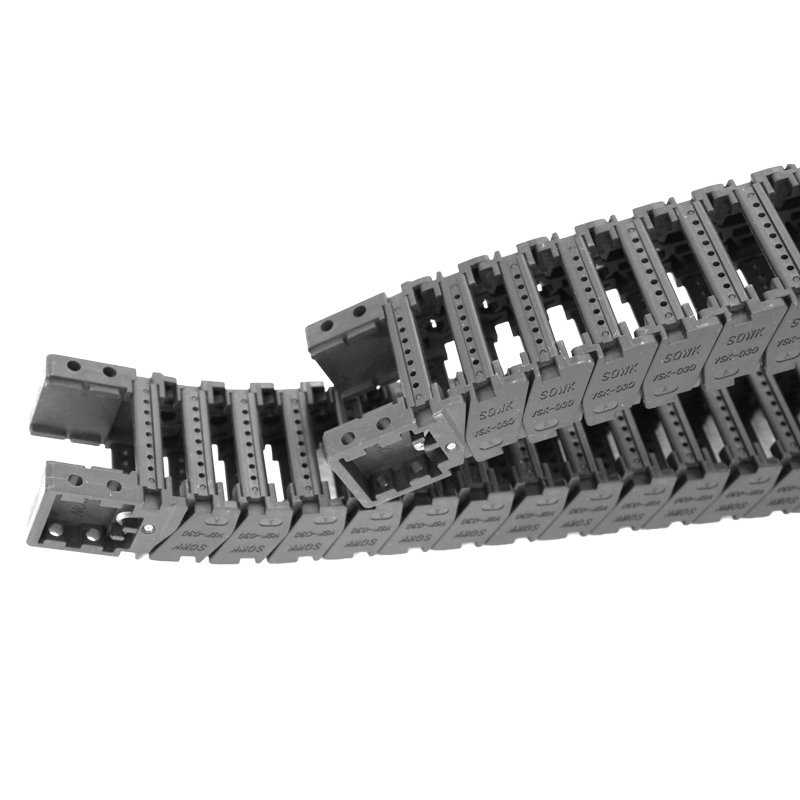

Plastic split loom is a non-metallic tubing made from high-density polyethylene (HDPE), which offers an excellent balance of flexibility and durability. The distinctive characteristic of split loom is its longitudinal split that runs along its length, allowing users to easily insert and remove wires as necessary. This feature makes it particularly versatile, as it can accommodate a variety of cable sizes while providing the necessary protection.

Benefits of Using Plastic Split Loom

1. Protection One of the primary benefits of plastic split loom is its ability to protect cables from abrasion, cuts, and environmental damage. This is especially important in settings where cables are subject to wear and tear, such as in automotive applications or industrial environments.

2. Cable Organization Split loom helps to keep multiple cables organized, reducing clutter and making it easier to identify individual wires. This organization not only enhances the aesthetic appeal of a workspace but also simplifies troubleshooting and maintenance.

3. Flexibility The flexibility of plastic split loom allows it to bend and twist easily, making it suitable for a wide range of applications. Whether you need to route cables around corners or along uneven surfaces, split loom can adapt without compromising the integrity of the cables inside.

4. Cost-Effective Compared to other cable management solutions, plastic split loom is relatively inexpensive. Its lightweight nature also allows for easy installation without requiring specialized tools or skills.

plastic split loom

5. Ease of Use The split design offers convenience, allowing for quick installation and removal of cables. Users can simply open the loom, insert the wires, and snap it shut, saving time and effort during the wiring process.

Applications of Plastic Split Loom

Plastic split loom is used in a variety of applications, spanning multiple industries

- Automotive In vehicles, split loom is employed to protect wiring harnesses from heat, chemicals, and mechanical wear. It helps maintain the integrity of electrical systems, ensuring reliable vehicle operation.

- Home and Office Whether it’s behind a television or along a desk, split loom is ideal for managing cables from computers, gaming consoles, and entertainment systems. It minimizes clutter and potential hazards associated with loose cables.

- Industrial In industrial settings, split loom provides heavy-duty protection for cables in machinery and equipment. This is vital in environments where cables are exposed to movement, vibration, and harsh conditions.

- DIY Projects For hobbyists and DIY enthusiasts, plastic split loom is often utilized in home projects involving electronics, ensuring that wires are neatly organized and protected for optimal performance.

Conclusion

Plastic split loom is an invaluable tool in the realm of cable management. Its combination of flexibility, durability, and cost-effectiveness makes it an ideal choice for a wide range of applications. By investing in plastic split loom, individuals and businesses can ensure their cables are well-organized, protected, and visually appealing, ultimately contributing to a safer and more efficient environment. Whether you're a professional installer or a DIY enthusiast, incorporating plastic split loom into your projects can greatly enhance cable management and performance.