Plastic Flexible Cable Carrier Chains for Efficient Cable Management Solutions

The Versatility of Plastic Flexible Cable Carrier Chains

In today's modern manufacturing and technology-driven industries, the importance of efficient cable management cannot be overstated. One of the most innovative solutions for organizing and protecting cables is the plastic flexible cable carrier chain. These chains have emerged as a critical component in various applications, ranging from robotics to automated production lines, providing flexibility, durability, and ease of maintenance.

What is a Plastic Flexible Cable Carrier Chain?

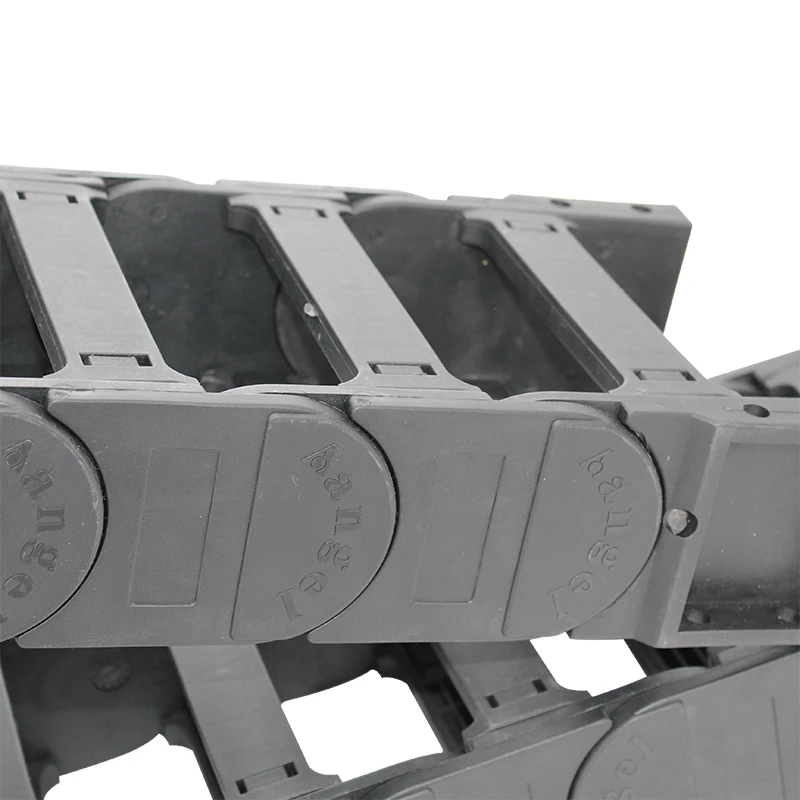

A plastic flexible cable carrier chain, often referred to as a cable drag chain or energy chain, is designed to guide and protect cables, hoses, and wires in dynamic applications. Unlike traditional fixed conduit systems, these chains allow for smooth movement and bending in multiple directions. Made from high-quality plastic materials, they offer both lightweight and robust properties, thus minimizing wear on cables and reducing the risk of damage due to friction or environmental factors.

Key Benefits

1. Flexibility and Mobility One of the most significant advantages of plastic flexible cable carrier chains is their ability to bend and flex while carrying cables. This feature is especially important in environments where machinery moves in various directions, such as CNC machines, robotic arms, and conveyor systems. The chains adapt to the movement without kinking or causing strain on the cables inside.

2. Durability Plastic is chosen for its resilience and resistance to factors like moisture, chemicals, and UV radiation. These properties ensure that plastic cable carrier chains can withstand harsh conditions, enhancing their longevity and reducing the need for frequent replacements. This durability is essential in industrial settings where downtime can be costly.

plastic flexible cable carrier chain

3. Ease of Installation and Maintenance Plastic flexible cable carrier chains are designed for user-friendly installation. Their modular design allows for easy expansion and modification. Additionally, maintenance is simplified as these chains can be cleaned and inspected without requiring significant disassembly. This ease of access further contributes to increased operational efficiency.

4. Cost-Effectiveness While investing in quality cable management solutions is important, plastic flexible cable carrier chains offer a cost-effective option for many businesses. Their durability reduces the frequency of replacements and repairs, leading to lower long-term costs. Additionally, their lightweight nature can contribute to energy savings in applications where weight and load are critical factors.

Applications

The applications for plastic flexible cable carrier chains are vast and varied. They are commonly used in

- Robotics In robotic systems, where arms and joints must move freely and accurately, cable carrier chains help to maintain cable integrity while allowing unobstructed movement. - CNC Machinery CNC machines benefit from cable management solutions that allow for smooth operation without cable tangling, thereby enhancing precision and productivity. - Automated Conveyor Systems In conveyor systems, these chains help manage power and data cables, ensuring smooth operation as products move from one stage to another.

Conclusion

In conclusion, plastic flexible cable carrier chains are an indispensable part of modern cable management solutions in dynamic environments. Their flexibility, durability, ease of installation, and cost-effectiveness make them an optimal choice for a wide range of industries. As technology continues to advance and machinery becomes more complex, the need for effective cable management will only grow, solidifying the role of plastic flexible cable carrier chains as vital components of industrial success. Whether in manufacturing, robotics, or beyond, these chains are leading the way in innovations for efficient and reliable cable management.